Daily Maintenance and Care Methods for Heating Mats

2025-12-18The core of daily maintenance and upkeep of heating seats is to protect the heating element, maintain electrical safety, and extend material life. Targeted measures should be taken according to their different usage scenarios and material characteristics, while avoiding operations that may damage the product. The following are detailed maintenance methods by dimension:

1、 Universal basic maintenance (applicable to all types of heating seats)

This type of operation is a prerequisite for ensuring the safe operation of the floor heating seat and needs to be performed before and after each use or regularly.

Check before use

- Electrical safety inspection: Before each power on, check whether the power cord is damaged, whether the plug is loose, and whether there is blackening or oxidation at the wiring. If the above problems exist, stop using immediately and contact after-sales. It is strictly prohibited to disassemble and repair on your own.

- Appearance inspection: Observe whether there are scratches, bulges, and accumulated stains on the surface of the heating seat. If the surface is damaged, waterproof sealing treatment should be carried out first (special insulation waterproof tape can be applied for household use, and the outer sheath needs to be replaced for industrial use) to prevent moisture and short circuit of the internal heating element.

Protection during use

- Prohibit folding and heavy pressure: Avoid folding, rolling, or placing sharp objects on the heating mat to prevent the internal heating wire from breaking or the heating film from being damaged; Household mattresses should not be powered on when folded, while industrial equipment should ensure a tight fit with the surface of the equipment without any hanging or squeezing.

- Control usage duration and temperature: Control the duration of single use according to the instructions (recommended for household use not exceeding 8 hours, industrial use should not exceed 24 hours of continuous operation and should be stopped for heat dissipation), to avoid long-term high-temperature operation accelerating material aging; During sleep, it is necessary to set the temperature to low or activate the timer function to reduce the load on the heating element.

Clean after use

- Power off cooling: Before cleaning, the power plug must be unplugged and the hot seat must be completely cooled before operation to prevent high temperature burns or electric shock.

- Gentle cleaning: Use a wrung out damp cloth to wipe the surface dust. For stubborn stains, dip a small amount of neutral cleaner and gently wipe. Do not use strong acid or alkali cleaners to avoid corroding the surface material; After cleaning, it needs to be dried before storage or use, and should not be exposed to direct sunlight.

2、 Special maintenance for different scenarios

Home use scenario (mattress/sofa/bathroom heating mat)

Mattress style:

- Regularly remove the surface cover (if removable) for cleaning, and do not directly wash the heating seat body with water (only wipe it off); When storing, lay flat or roll into a cylinder with a diameter of ≥ 30cm, avoid folding, store in a dry and ventilated place, away from damp wardrobes or floors.

- Avoid using other heating devices such as electric blankets and hot water bags on the heating seat to prevent damage to the heating element caused by excessive local temperature.

Waterproof design for bathroom:

- After each use, dry the surface water and regularly check whether the IP waterproof sealing strip is aging and cracking. If it cracks, replace the sealing strip to ensure waterproof performance; The splash box of the power socket should be kept closed to prevent water vapor from entering the socket and causing a short circuit.

Industrial scenario (equipment insulation/pipeline heat tracing heating mat)

Equipment outer wall design:

- Regularly check whether the outer insulation layer has fallen off, and if it has fallen off, it should be promptly replenished to reduce heat loss while protecting the heating mat from industrial dust and oil pollution; Every six months, use a multimeter to check the resistance value of the heating seat. If the deviation from the factory value exceeds ± 10%, the machine should be stopped for maintenance to prevent uneven heating.

- The heating mat that comes into contact with chemical media should be checked quarterly for corrosion spots on the surface fluoroplastic sheath. If it is damaged, it should be replaced immediately to prevent the medium from penetrating into the interior and damaging the heating element.

Pipeline heating system:

- After the winter heating is stopped, it is necessary to clean the frost and impurities on the surface of the pipeline, check whether the fixing buckle of the underground heating seat is loose, reinforce it again, and do a good job of moisture-proof protection; Outdoor pipeline models need to be additionally wrapped with sunscreen and anti freezing protective sleeves to prevent low-temperature cracking in winter and UV aging in summer.

Agricultural scenario (greenhouse soil/seedling box heating mat)

Soil burial fee:

- After each season of planting, dig out the heating mat (avoid violent pulling), clean the soil and roots attached to the surface, rinse with clean water and air dry, check whether the PE waterproof film is damaged, and repair the damaged area with special waterproof glue; Keep away from corrosive materials such as pesticides and fertilizers during storage to prevent material aging.

Nursery box model:

- Regularly wipe the surface with alcohol swabs to disinfect and remove residual roots of seedlings; When storing, place it in a dry cardboard box to prevent rodents and insects from biting the power cord and surface material.

3、 Prevention and emergency response of common faults

Core measures for preventing malfunctions

- Avoid frequent plugging and unplugging of plugs to reduce poor contact and oxidation of plugs; Household models should not use inferior power strips, while industrial models should be equipped with leakage protectors.

- When not in use for a long time, the power should be unplugged, cleaned and dried before storage. Every 3 months, power on and run for 10 minutes (at low temperature) to activate the heating element and prevent internal components from becoming damp and ineffective.

Emergency response

- If there is any odor, smoke, or local overheating during use, immediately cut off the power, stop using, and contact professional after-sales service. It is strictly prohibited to disassemble on your own; If there is a slight leakage, it is necessary to check whether the socket grounding is normal. If there is no grounding, a grounding device should be installed.

4、 Maintenance taboos

- It is strictly prohibited to wash or soak the heating mat body with water, even for IPX7 waterproof models, it should not be soaked in water for a long time.

- It is strictly prohibited to pry or puncture the surface of the heating seat with sharp tools to avoid damaging the internal heating element and circuit.

- It is strictly prohibited to self wire or replace components when the heating seat malfunctions. Non professional operations may cause safety accidents such as electric shock and fire.

Safety Assurance Mechanism of Heating Mats

2025-12-18The safety of a heating seat depends on product quality, usage standards, and scene adaptability. Qualified products have extremely low risks when used correctly, while inferior products or improper operation may cause hidden dangers such as electric shock, burns, and fires. This article provides a detailed introduction to the safety measures of heated seats.

1、 Core safety guarantee mechanism for qualified heating seats

Legitimate products will undergo multiple designs and certifications to reduce safety risks from the source, mainly including the following points:

Electrical Safety Certification:

Household insulated heating seat must pass 3C mandatory certification, which is the basic threshold for electrical safety, covering multiple tests such as leakage protection, insulation performance, flame retardancy, etc; Industrial grade heating mats also need to comply with industry standards to ensure electrical safety in complex environments.

Multiple temperature protection functions:

- Automatic temperature limiting: Equipped with a built-in temperature controller or PTC self limiting element, the surface temperature is controlled at 35-45 ℃ (a comfortable and safe range for human body), avoiding low-temperature burns or material aging caused by high temperature.

- Overheating power-off protection: When the thermostat fails, the built-in temperature fuse will automatically cut off the power at 50-60 ℃, fundamentally eliminating the risk of fire.

- Timer shutdown function: Household models are generally equipped with 1-8 hour timer to prevent users from forgetting to shut down and causing prolonged high-temperature operation.

Protection level adaptation design:

The product will label the IP protection level according to the usage scenario, such as:

- Bedroom/living room style: IPX4 splash proof, suitable for daily watering and mopping;

- Toilet/outdoor type: IPX6-IPX7 is waterproof, which can resist rainstorm scouring or short-term immersion, and prevent water vapor from invading the internal circuit and causing short circuit.

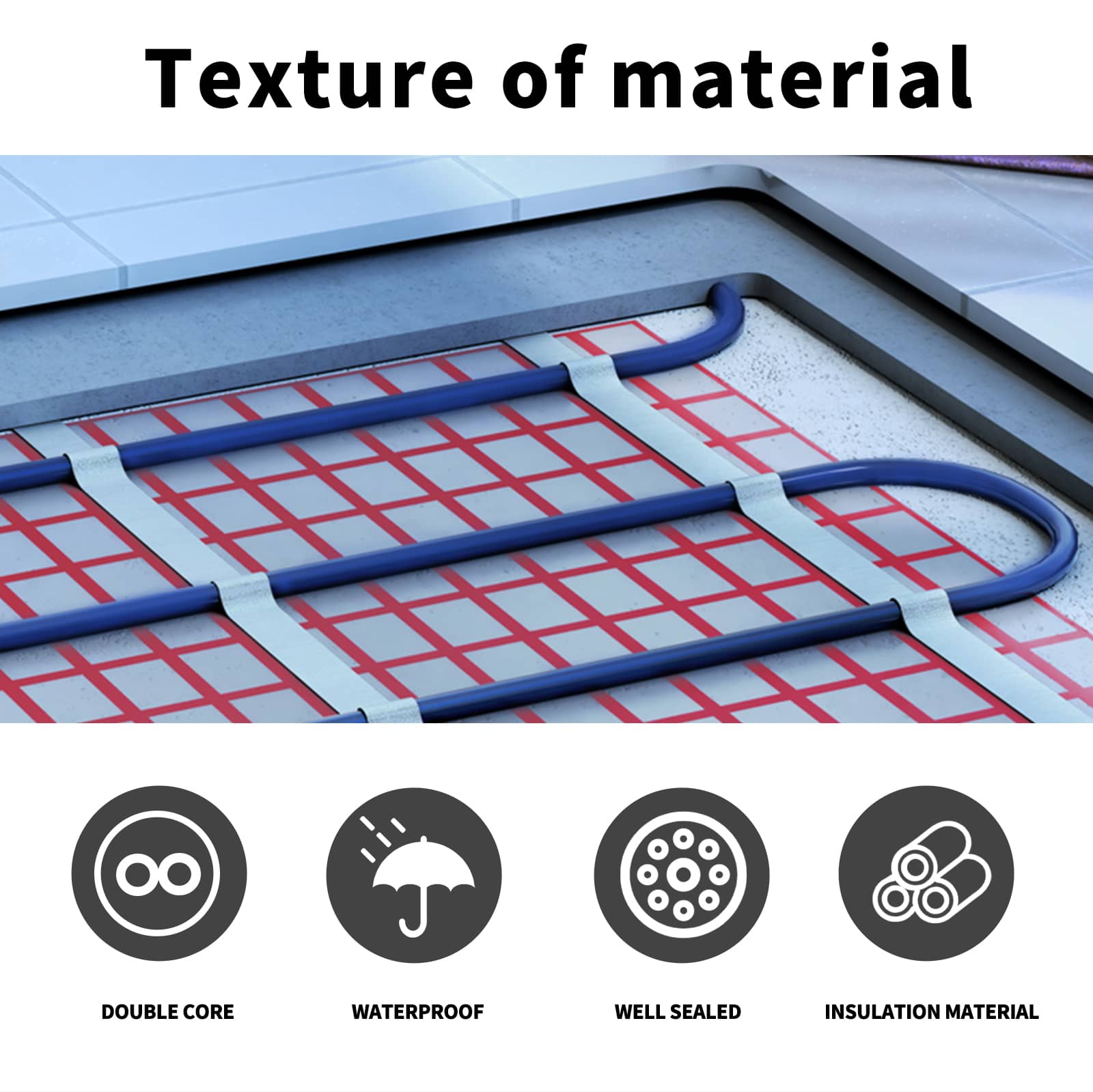

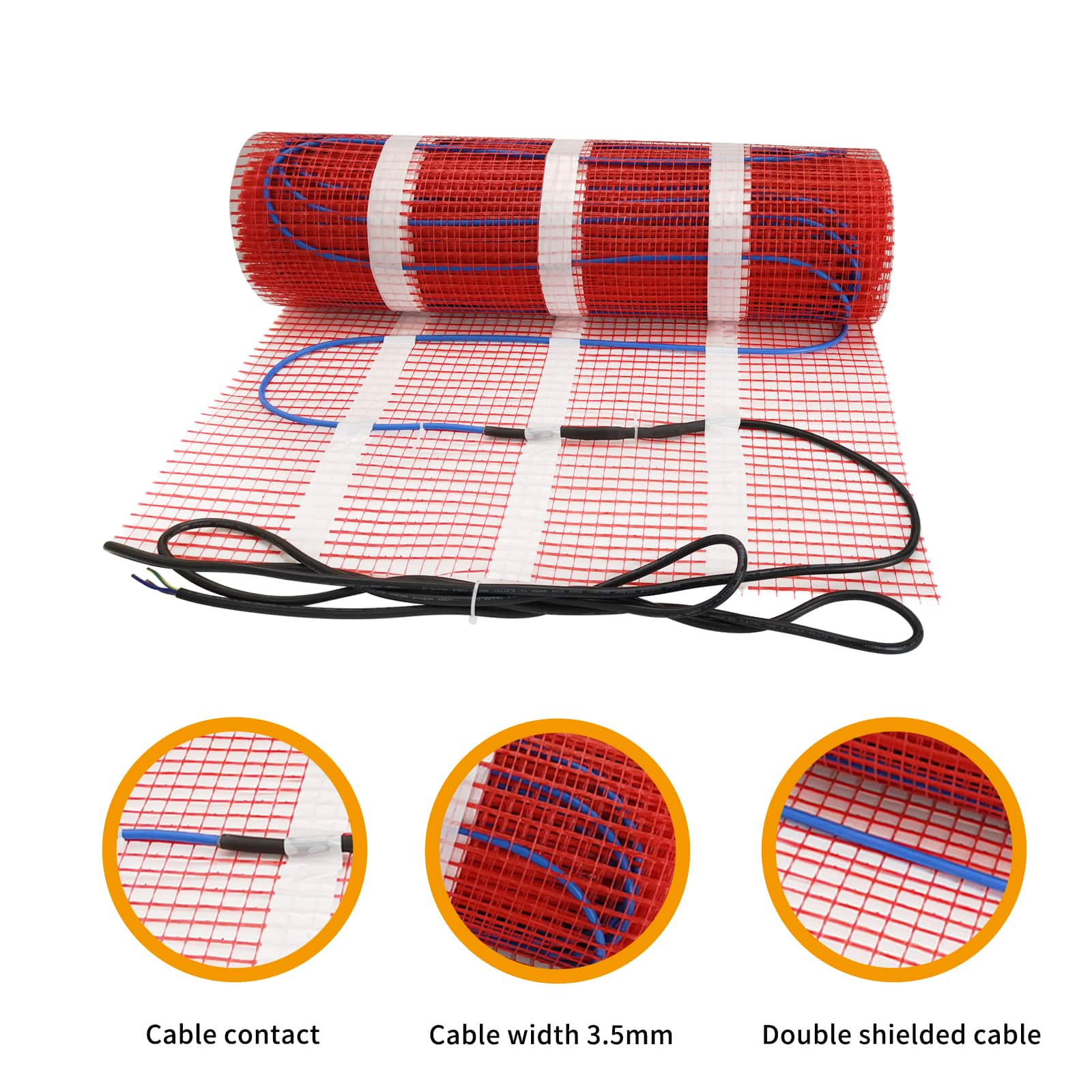

Material and structural safety:

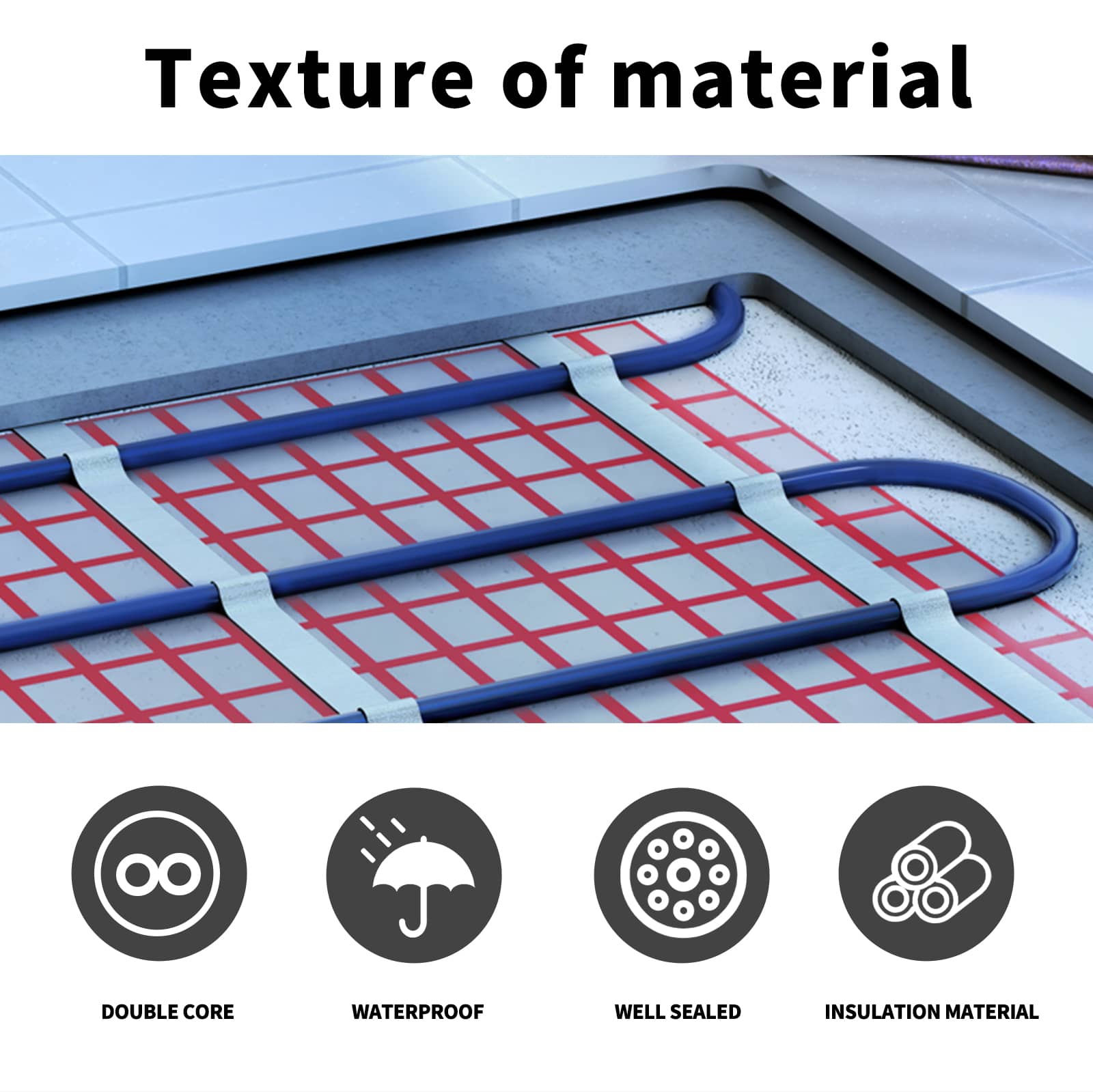

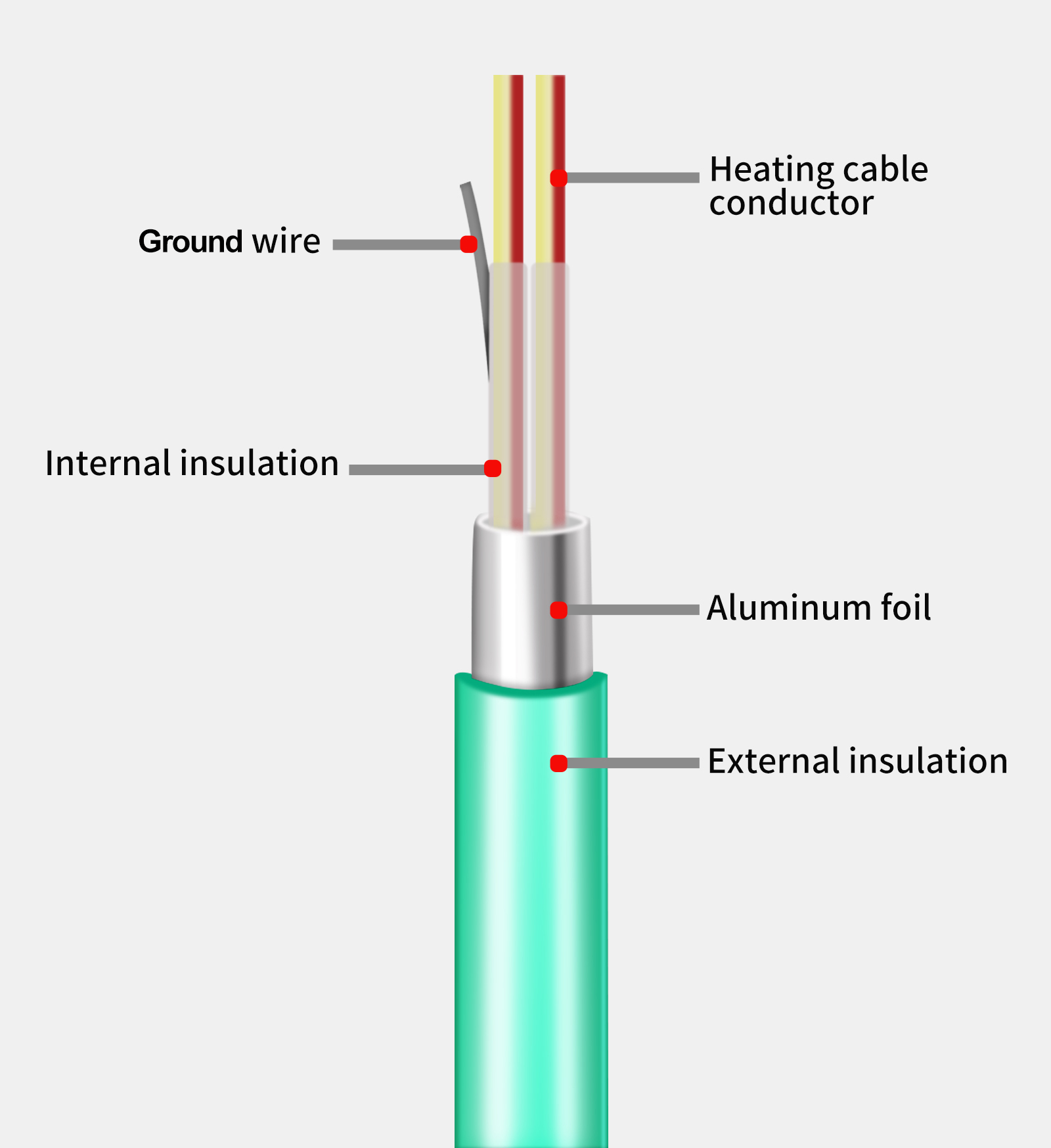

- The surface is made of flame-retardant and wear-resistant materials, which are not easy to burn and tear resistant;

- The heating element is wrapped in a double-layer insulation layer, and the power cord adopts a thick copper core and anti bending design. The plug is a three pin grounding plug, which can guide the current to the ground in case of leakage.

2、 Core principles for improving the safety of heating seats

Reject "three no products":

When purchasing, identify 3C certified heating seat, clear IP rating, and temperature control function, and do not buy products with low prices, no brand, or no manual.

Strictly match usage scenarios:

- The bathroom must be IPX7 waterproof and located at least 1.5 meters away from the shower area;

- For outdoor use, choose the IPX6 model that is cold resistant and wear-resistant to avoid sharp objects scratching the surface.

Standardized usage and operation:

- Do not fold or press the heating mat, do not cover flammable materials such as blankets or blankets;

- Single use for no more than 8 hours, set to low temperature or turn on timer during sleep;

- A thin sheet should be placed between the skin and the heating seat to avoid direct contact.

Regular inspection and maintenance:

Check the power cord for damage and the plug for oxidation every month, and stop using immediately if any abnormalities are found; When not in use for a long time, clean and dry before storing to avoid moisture.

Qualified heating seats are high safety heating products that can minimize risks as long as purchased through legitimate channels and used according to instructions; The core of safety hazards is not the product itself, but "inferior products" and "illegal operations". Minco heating products provide you with the safest and warmest protection.

Rectification Measures for Installation Process Defects of Heating Cables

2025-12-03The rectification of installation defects in heating cables must adhere to the principle of "power outage inspection first, defect classification by type, and post-rectification review and verification." For defects in core aspects such as laying, fixing, connection, protection, and supporting construction, precise corrective measures should be formulated to ensure the complete elimination of safety hazards and the restoration of system performance. Below are the specific rectification methods, operational key points, and acceptance standards for various types of defects:

1、 Rectification of laying defects: restore uniform heat dissipation and insulation integrity

Uneven spacing between insulated heating cables

Rectification measures:

- After the power is cut off, remove the fixed fixtures in the unqualified area, adjust the cable position according to the design spacing, and use a steel tape measure to review each group one by one;

- Local dense area: Disperse cables to standard spacing. If space is limited and dispersion is not possible, low-power density cables need to be replaced to avoid local overheating;

- Areas with excessive spacing: Supplement cable sections or increase the spacing between existing cables.

Operation points: After adjustment, fix it with a special clamp, with a spacing of ≤ 50cm (horizontal)/30cm (vertical) between fixing points, to avoid the cable shifting again;

Acceptance criteria: Scanning with infrared thermal imaging instrument, temperature difference ≤ 3 ℃, no local overheating area.

Inappropriate bending radius and excessive bending

Rectification measures:

- Slight bending: Slowly bend again to the standard radius, fix the bend with a clamp to avoid stress;

- Severe bending: Cut off the damaged section, replace with a new cable section, and prohibit direct straightening for continued use;

- Crossing narrow spaces: Install guide sleeves to guide cables to bend smoothly and avoid forced bending.

Operation points: Use hands to assist in shaping when bending, and do not use tools to forcefully break; After bending the MI cable, insulation resistance needs to be tested;

Acceptance criteria: There is no deformation or cracking of the sheath at the bend, and the insulation resistance meets the standard.

Cable overlap and crossing

Rectification measures:

- Overlap: Separate the overlapping cables and re fix them according to the standard spacing. If the overlapping section has experienced overheating and discoloration of the sheath, the cable section needs to be replaced;

- Intersection: Adjust the cable routing to avoid crossing. If crossing is necessary, use insulation gaskets to isolate the intersection with a spacing of ≥ 20mm;

- Ground heating overlapping ring: Cut off the overlapping part, reconnect it, or adjust the cable routing as a whole to eliminate the overlap.

Operation points: After rectification, check that the cable sheath is not damaged and there is no local overheating during power on testing;

Acceptance criteria: No overlap or crossing, local temperature ≤ 80% of cable temperature resistance.

The cable is not tightly attached to the controlled object

Rectification measures:

- Ground heating: Open the filling layer/insulation layer, fix the cable on the surface of the insulation layer with aluminum foil tape, and ensure that the cable is in full contact with the filling layer; If there are gaps in the insulation layer, fill them with insulation mortar;

- Pipeline insulation: Remove the insulation cotton, tightly attach the cable to the surface of the pipeline with aluminum foil tape, re wrap the insulation cotton, and fix the outer layer with zip ties;

- The surface of the controlled object is uneven: first level the ground, and then fix the cable.

Operation points: After bonding, gently press the cable with your hand without looseness to ensure heat transfer efficiency;

Acceptance criteria: The heating rate meets the standard (ground heating ≤ 1 hour, pipeline insulation ≤ 2 hours).

2、 Fixed defect rectification: avoid cable displacement and mechanical damage

Improper fixing method (iron wire, plastic zip ties)

Rectification measures:

- Remove iron wires and plastic ties, replace stainless steel clamps or ceramic insulators;

- If the wire has scratched the sheath: wrap the damaged area with insulating tape and replace the cable section for a long time;

- Sharp fixed fixture: Polish the edge of the fixture to a rounded shape, or install rubber pads to avoid scratching the cable.

Operation points: The tightening force of the clamp is moderate, and the Minco heating cable sheath has no obvious deformation;

Acceptance criteria: firm fixation, no looseness, and no scratches or damage to the protective sheath.

Excessive spacing between fixed points and cable sagging

Rectification measures:

- Add fixing points: add clamps at intervals of "horizontal ≤ 50cm, vertical ≤ 30cm", and re straighten and fix the sagging section;

- Severe sagging in vertical laying: Install load-bearing clamps in the middle of the cable to disperse gravity and avoid sheath stretching;

- Corner/turning: Fixed points must be added to ensure that there is no risk of cable displacement.

Operation points: After fixation, the cable should not sag significantly;

Acceptance criteria: After 24 hours of power on operation, the cable should not shift or sag.

Excessive fixing force and cable compression

Rectification measures:

- Loosen the overly tight clamp and adjust the force to "no displacement of the cable and no deformation of the sheath";

- Sheath deformed: If the insulation resistance meets the standard, it can be retained for use; If the insulation resistance decreases, the cable section needs to be replaced;

- Replace the buffer clamp: Install a rubber pad between the clamp and the cable to distribute pressure.

Operation points: After adjustment, gently pull the cable by hand without displacement, and ensure that the sheath is not dented;

Acceptance criteria: The insulation resistance meets the standard, and the cable power is normal.

3、 Rectification of protective defects: Enhancing environmental adaptability

Insufficient moisture-proof and waterproof measures

Rectification measures:

- The joint is not sealed: replace the waterproof junction box, fill the box with sealant, and press the cable inlet with a waterproof joint;

- Cable end sealing cap detachment: Reinstall the dedicated sealing cap, wrap the sealant, and ensure no gaps;

- Outdoor exposed joints: Install rain covers and reserve drainage holes at the bottom of the junction box to prevent rainwater accumulation.

Operation points: Conduct immersion test after sealing;

Acceptance criteria: No water seepage or leakage, insulation resistance meets the standard.

Lack of protection against high temperature/corrosive environments

Rectification measures:

- High temperature scenario: Install ceramic gaskets or heat sinks between cables and high-temperature equipment to avoid direct contact;

- Corrosive environment: Replace the corrosion-resistant sheathed cable, or wrap anti-corrosion tape on the outside of the original cable and cover it with an anti-corrosion sleeve;

- Insufficient insulation layer: Thicken insulation cotton and seal the outer layer with aluminum foil cloth to reduce heat loss and corrosion medium invasion.

Operation points: Test the temperature of the cable sheath after rectifying the high temperature scenario, and ensure it is ≤ the upper limit of the cable's temperature resistance;

Acceptance criteria: The cable shows no signs of corrosion or overheating and operates stably.

4、 Overall acceptance process after rectification

Appearance inspection: The cable laying is uniform, firmly fixed, the joint sealing is intact, the protective measures are in place, and there are no obvious defects;

Electrical performance test: Insulation resistance ≥ 50M Ω (dry state), grounding resistance ≤ 4 Ω, leakage protection test meets the standard;

Heating performance test: The heating rate, temperature uniformity, and temperature control accuracy meet the standards;

Trial operation acceptance: Continuous power on operation for 24 hours without any abnormalities such as tripping, heating, leakage, etc. Record and archive the operation data.

The core of rectifying defects in the installation process of heating cables is "targeted elimination of hidden dangers and restoration of design performance", prioritizing the treatment of safety defects (such as leakage, short circuit, local overheating), and then rectifying performance defects (such as slow heating and uneven temperature). During rectification, original accessories and specialized tools must be used, and key processes such as joint production and grounding must be operated by professional personnel to avoid secondary defects. After rectification, comprehensive testing and verification must be conducted to ensure the safe, stable, and efficient operation of the system.

How should heating cables avoid proximity to low-temperature objects/areas

2025-11-26Avoid placing heating cables near low-temperature objects or areas. The core approach involves four key measures: "physical isolation, optimized installation, enhanced insulation, and power adjustment" to minimize heat loss caused by low-temperature conduction and cold radiation, ensuring efficient heating and uniform temperature distribution.

1.First, clarify the "low-temperature objects/areas to be avoided."

First, accurately identify the sources of risk, plan the laying routes in advance, and avoid direct contact or close proximity.

- Low-temperature objects: exterior walls, windows (glass/window frames), doors, basement floor slabs, cold water pipes, air conditioning condensate pipes, and metal components (high thermal conductivity);

- Low-temperature areas: Room corners (poor air circulation, accumulation of cold airflows), window sill areas (cold radiation from glass), doorways (frequent door openings allowing cold air infiltration), and exposed outdoor pipeline sections.

2.Core measures: Physical isolation and enhanced insulation

By adding insulation layers or isolation structures to block low-temperature conduction and reduce heat loss:

Additional insulation layer added to low-temperature areas/object surfaces.

Ground heating scenario:

- Under the window and on the inner side of the exterior wall, on the basis of the original insulation layer, an additional 5-10mm thick high-density extruded board is added, and the joint is sealed with aluminum foil tape to form a "double insulation";

- The thickness of the insulation layer in the basement or first floor should be increased by 30% compared to the standard to avoid downward heat dissipation from the ground.

- If the pipeline needs to pass through outdoor or low-temperature areas, wrap thick insulation cotton around the outside of the cable, and then cover it with aluminum foil or iron sheet outer protective layer to prevent direct contact of cold air with the cable and pipeline.

Maintain a safe distance between cables and low-temperature objects

- Ground heating: The distance between the cable and the inner surface of the exterior wall and the edge of the window frame should be ≥ 100mm (which can be relaxed to 150mm based on the original standard), to avoid the cable being tightly attached to the low-temperature wall;

- Pipeline insulation: The distance between the cable and the cold water pipeline or metal components should be ≥ 50mm. If they must cross, insulation sleeves should be used to isolate the two pipelines at the intersection to prevent low temperature conduction to the heating cable;

- It is prohibited to lay cables directly on the surface of metal components, and ceramic insulators or insulation pads should be used to separate them (with a spacing of ≥ 20mm).

3.Optimize laying: adjust spacing and power locally to compensate for heat loss

Low temperature areas experience rapid heat loss, which can be compensated for by increasing spacing and local power to avoid slow heating:

Encrypt the spacing between cables in low-temperature areas

- Ground heating: The normal area spacing should be based on the design value, and the spacing between low-temperature areas such as under windows and corners should be reduced by 20% to 30% to increase the heating power per unit area;

- Pipeline insulation: The spiral winding spacing of cables in low-temperature sections (such as outdoor exposed sections) is reduced by 1/3 compared to normal sections, increasing local heat density.

Select high power density cables for special areas

- If the heat loss in the low-temperature area is extremely fast, it can be locally replaced with high-power density cables to directly enhance the heating capacity;

- Attention: High power cables need to be equipped with suitable temperature controllers (with sufficient output power), and the spacing should not be too small to avoid local overheating.

4.Detail protection: reduce the accumulation of cold air flow and low temperature infiltration

Optimize room ventilation and sealing

- In low-temperature areas such as under windows and at doorways, it is necessary to ensure good sealing of doors and windows (replacing aging sealing strips, installing door bottom stop strips) to reduce the infiltration of cold air;

- Avoid setting frequently open ventilation openings in the heating area. If ventilation is required, choose to ventilate for a short period of time after reaching the heating standard to avoid continuous low-temperature interference during ventilation.

Prevent the formation of "cold air circulation" in low-temperature areas

- When using ground heating, a 5-10cm heat dissipation gap can be reserved in the area under the window (such as furniture not tightly attached to the ground under the window) to allow the heated air to form convection and reduce the accumulation of cold air flow;

- High rise spaces such as industrial workshops and low-temperature areas (such as corners and floors) can be equipped with small circulating fans to promote air flow and avoid the continuous existence of local low-temperature areas.

5.Special handling for special scenarios

Outdoor pipelines or low-temperature environments (below -10 ℃)

- Wrap the outer side of the cable with "insulation cotton+waterproof outer protective layer" to completely isolate rain, snow, and cold air;

- Install moisture-proof sealing caps at both ends of the pipeline to prevent moisture from entering the insulation layer and causing icing, indirectly affecting cable heat dissipation.

Ground heating near large areas of glass

- Stick insulation film on the inside of the glass (to reduce cold radiation), and lay aluminum foil reflective film on the insulation layer under the window to reflect the heat generated by the cable upwards and reduce downward loss;

- When laying cables, the area under the window can be encrypted using a "U-shaped folding" method to ensure sufficient heating power in that area.

Through the above measures, the impact of low-temperature objects/areas on heating cables can be significantly reduced, ensuring that the heating rate meets the standard and the temperature distribution is uniform. If the area of the low-temperature zone is too large (such as the entire exterior wall without insulation), it is recommended to first carry out insulation renovation of the building main body, and then install heating cables to avoid continuous low heating efficiency due to insufficient basic insulation.

What may be the installation process defects of heating cables

2025-11-26The installation process defects of heating cables directly affect system safety, heating effect, and service life. The core focus is on five aspects: laying, fixing, connecting, protecting, and supporting construction. The specific types, manifestations, and hazards of defects are as follows, which are convenient for on-site investigation and rectification:

1、 Defects in laying process: directly causing uneven heating and insulation damage

Cable spacing deviation too large/too small

- Defect manifestations: failure to lay according to the design spacing, local dense stacking, and uneven spacing between edge areas;

- Harm: Too small spacing can cause local overheating, accelerate insulation aging, and too large spacing can lead to insufficient temperature, with an overall temperature difference exceeding 3 ℃;

- Typical scenario: Difficulty in laying in the corners of ground heating walls and around pipelines, with cables being randomly wrapped; The spacing was not controlled during the spiral winding of pipeline insulation.

The bending radius does not meet the standard and is excessively bent

- Defect manifestation: Cable bending radius less than the manufacturer's requirements, right angle bending, repeated bending;

- Harm: Cracking of metal sheath, breakage of magnesium oxide insulation layer, or damage of polymer insulation layer (self limiting heating cable), causing a decrease in insulation resistance and leakage;

- Common causes: using tools to forcefully break cables during construction, and forcibly bending cables when crossing narrow spaces.

Overlapping and cross laying of cables

- Defect manifestation: Multiple cables crossing, single cable overlapping on its own;

- Harm: The heat at the overlapping area cannot be dissipated, and the local temperature exceeds the upper limit of the cable's temperature resistance, causing the insulation layer to melt, short circuit, and even fire;

- Mistake prone point: intentionally overlapping and winding cables to increase heating power during pipeline insulation.

The cable is not tightly attached to the controlled object

- Defect manifestation: During ground heating, the cable is suspended in the gap of the insulation layer, and during pipeline insulation, the cable is not tightly attached to the surface of the pipeline;

- Harm: Decreased heat transfer efficiency, slow heating rate, and low temperature in the suspended area;

- Common causes: uneven surface of the controlled object and failure to compact the cable during fixation.

2、 Fixed process defects: causing cable displacement and stress damage

Improper fixing method can damage the cable

- Defect manifestation: Fixed with iron wire and plastic cable ties (iron wire scratches the sheath, plastic cable ties melt at high temperature), sharp fixing fixtures;

- Hazard: Cable sheath damage, exposed insulation layer, causing electrical leakage; After the plastic cable tie melts, the cable shifts and the spacing is disrupted;

- Correct requirement: Fix with stainless steel clamps and ceramic insulators, and the fixture should be round and free of edges and corners.

The fixed point spacing is too large, causing the cable to sag

- Defect manifestation: Horizontal laying fixed point spacing>50cm, vertical laying>30cm, or no fixed point set in corners or turns;

- Harm: Due to self weight sagging and displacement, the originally uniform spacing of the cable is damaged, and local stretching causes the sheath to crack;

- Typical scenario: When laying vertically on the walls of a tall space, the fixing points are not encrypted as required, and the cables sag in the middle section.

Excessive fixing force, squeezing the cable

- Defect manifestation: excessive force when tightening the clamp, squeezing the cable sheath (such as deformation of MI cable metal sheath, depression of insulation layer of self limiting cable);

- Harm: The magnesium oxide insulation layer inside the MI cable is broken, and the heating core of the self limiting cable is compressed, resulting in local power abnormalities (overheating or no heating);

- Judgment method: After fixing, the cable sheath should have no obvious deformation, and the cable should be gently pulled by hand without displacement.

3、 Connection process defects: the weakest link in the system, which can easily cause leakage and short circuits

Improper joint production

- Defect manifestation:Failure to seal the cables in a timely manner after cutting them on site, and failure to fill the joints with sealant;

- Harm: Decreased insulation resistance, leakage, and even short circuit burning at the joint;

- Correct requirement: Priority should be given to using prefabricated joints from the manufacturer, and on-site joints should be welded firmly and sealed in multiple layers.

The wiring terminals are loosely connected or crimped

- Defect manifestation: The wire is directly twisted with the temperature controller/power terminal, and the terminal screws are not tightened;

- Harm: Excessive contact resistance at the virtual connection point can cause heating and burn out the terminals, and even lead to a fire; Unstable current transmission and insufficient heating power of cables;

- Mistake prone: Multiple wires are inserted into the terminal without being tightly twisted, or the copper nose does not match the cross-sectional area of the wire.

Violation, interference or damage in the laying of the circuit

- Defect manifestation:The cable did not pass through the protective tube when passing through the wall/equipment;

- Harm: Electromagnetic interference can cause the thermostat to malfunction, cables to start and stop frequently, and wires to break, leading to short circuits;

- Correct requirement: Separate the installation of strong and weak electricity, and use metal protective pipes at the crossing points.

4、 Defects in protective technology: insufficient ability to resist the environment, accelerated aging

Insufficient moisture-proof and waterproof measures

- Defect manifestation:The joints in outdoor/humid environments (such as basements and pipeline wells) are not equipped with waterproof junction boxes, and the junction boxes are not sealed;

- Harm: Moisture seeps into the insulation layer of the insulated heating cable, causing a decrease in insulation resistance and corrosion of the sheath;

- Typical scenario: When insulating outdoor pipelines, the joints are exposed to rain and snow without rain covers.

Lack of protection against high temperature/corrosive environments

- Defect manifestation:Corrosion resistant sheathed cables have not been used in corrosive environments, nor have they undergone anti-corrosion treatment;

- Harm: Overheating, aging, corrosion and damage of cable sheath, shortening the service life by 30%~50%;

Grounding process defects

- Defect manifestation: The metal sheath of the cable, junction box, and temperature controller housing are not grounded, or the grounding resistance is greater than 4 Ω;

- Harm: When the protective sheath is damaged, electric leakage occurs, making it unable to enter the ground and causing electric shock accidents;

- Correct requirement: Use a yellow green grounding wire of ≥ 2.5mm ² and multiple grounding points.

5、 Common process defect investigation methods

- Appearance inspection: The cable is free of scratches, deformations, overlaps, firmly fixed, and the joint seal is intact;

- Insulation resistance test: Use a 500V megohmmeter to measure the insulation resistance of the cable to ground, and it is qualified if it is ≥ 50M Ω (dry state);

- Power on test: After 1 hour of power on, scan with an infrared thermal imaging device, and there should be no local overheating (>80% of cable temperature resistance) or low temperature areas (temperature difference from normal areas>3 ℃);

- Joint inspection: There is no heating at the joint (measured with a thermometer, which should be close to the ambient temperature) and no leakage.

The installation process defects of heating cables mainly include "non-standard connection, improper fixation, uneven laying, and lack of protection", among which joint production and insulation protection are the most prone to safety accidents. It is recommended to provide specialized training for personnel before construction, strictly follow the manufacturer's instructions and specifications for operation, and have professional personnel complete key processes. After installation, defects should be checked item by item to avoid operation with defects.

Analysis of the Safety of Self-Limiting Temperature Carbon Fiber Heating Films

2025-11-11Analysis of the Safety of Self-Limiting Temperature Carbon Fiber Heating Films: Principles, Advantages, and Risk Prevention

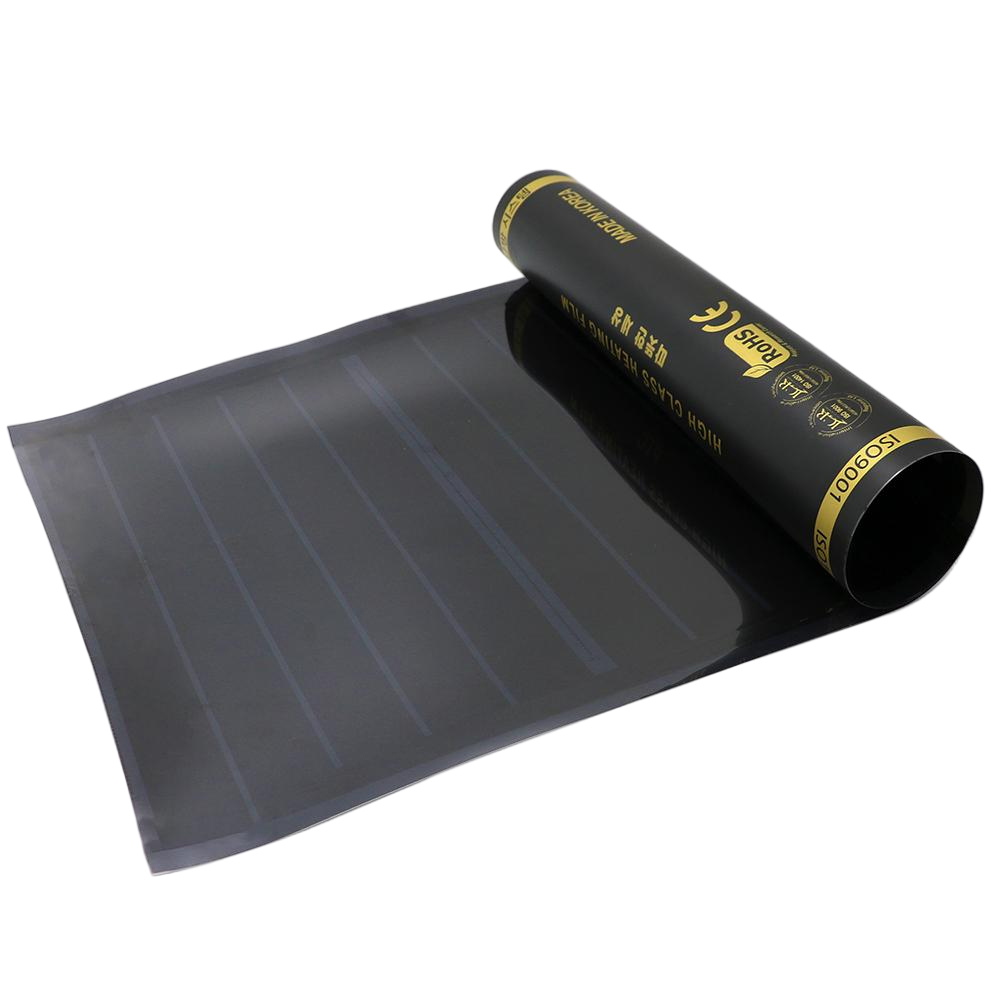

As a new type of electric heating material, self-limiting temperature carbon fiber heating films are widely used in fields such as building heating, household appliance hot compresses, and pipeline insulation due to their characteristics of energy saving, flexibility, and uniform heating. Their safety is the core concern of users, and a comprehensive judgment of their safety attributes requires a comprehensive analysis from three aspects: technical principles, core safety advantages, potential risks, and prevention measures.

1.First, Understand: The "Safety Core" Of Self-limiting Temperature Carbon Fiber Heating Film — the Principle of Self-limiting Temperature Technology

The self-limiting temperature function is the key that distinguishes this type of product from ordinary carbon fiber heating films, and it is also the "underlying guarantee" for its safety performance. The principle can be popularly understood as "actively braking when the temperature is too high":

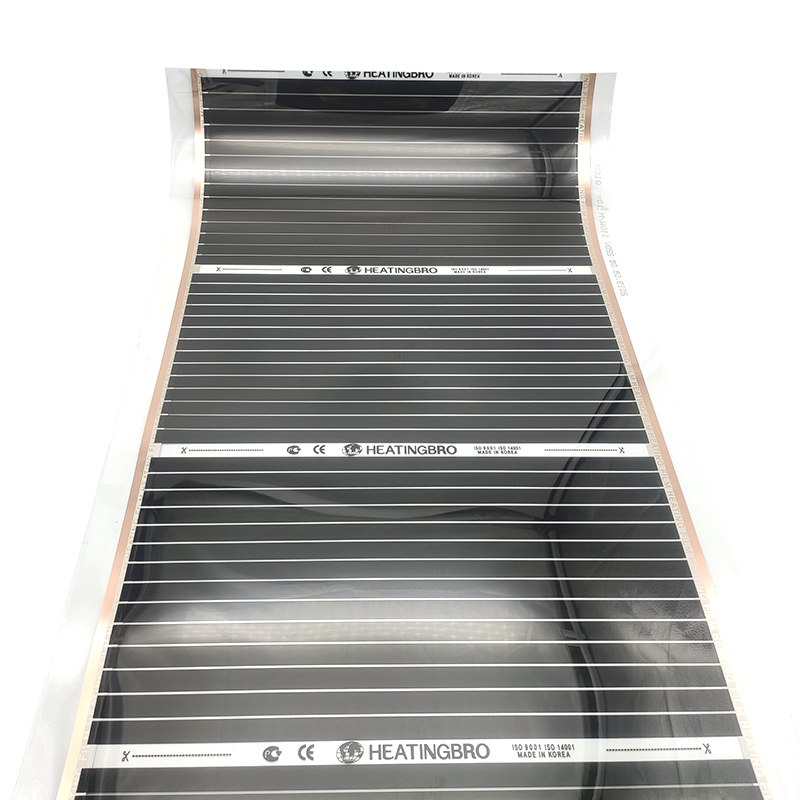

- The core layer of the heating film is composed of a composite of carbon fiber heating wires and self-limiting temperature polymer materials (such as modified polyethylene, conductive composite materials);

- When the ambient temperature is low, the conductive paths in the self-limiting temperature material are dense, allowing current to pass smoothly, and the carbon fiber heating wires generate heat normally (with stable power);

- When the temperature rises to a preset "threshold" (usually determined by the material formula, such as 40-80℃), the self-limiting temperature material will undergo a "microstructural change" due to thermal expansion — the conductive paths are stretched and their number decreases, resulting in an increase in resistance;

- After the resistance increases, the current in the circuit automatically decreases, and the heating power decreases accordingly, preventing the temperature from continuing to rise; if the temperature drops, the conductive paths recover, and the power also rises, achieving "automatic temperature regulation with no risk of overheating".

2. "Safety Advantages" of Self-Limiting Temperature Carbon Fiber Heating Film: Multiple Protections from Materials to Design

In addition to the core self-limiting temperature technology, its safety is also reflected in material properties, structural design, and compliance, which can be specifically summarized into 4 points:

- No local overheating, avoiding fire hazards:If ordinary heating films have "local damage or poor line contact", they are prone to "hot spots" (sudden local temperature rise). However, even if self-limiting temperature ones are subject to local force or uneven environment, they can limit the temperature through resistance adjustment, preventing surrounding materials (such as walls, carpets, furniture) from being ignited due to overheating.

- Strong insulation, preventing leakage risks:The heating layer of regular products will be wrapped with double insulation layers (such as temperature-resistant polyvinyl chloride, silicone rubber), with an insulation resistance usually ≥100MΩ (far higher than the national standard requirement of ≥2MΩ), which can effectively insulate the current. Even when used in humid environments (such as bathrooms, kitchens), it can reduce the risk of electric leakage.

- High temperature and corrosion resistance of materials, stable service life:Carbon fiber itself has excellent high-temperature resistance (long-term service temperature can reach above 150℃, far exceeding the self-limiting temperature threshold), and is resistant to acids, alkalis, and not easy to oxidize; the self-limiting temperature polymer materials have undergone aging tests, and their service life can reach 10-15 years under normal use, avoiding short circuits and damage caused by material aging.

- Compatible with safety protection devices, double safeguards:In practical applications, self-limiting temperature heating films are usually used together with thermostats and residual current devices (RCDs): The thermostat can preset the maximum temperature (such as 50℃), forming a "double temperature limit" with the self-limiting temperature function; the residual current device can cut off the circuit within 0.1 seconds when there is a leakage (current ≥30mA), further reducing the risk of electric shock.

3.Unignorable "Potential Risks": Mostly Originating from "Non-product Itself" and Requiring Targeted Prevention and Control

The safety hazards of self-limiting temperature carbon fiber heating films are mostly not from "self-limiting temperature technical defects", but from external factors such as substandard product quality, improper installation, and illegal use. The common risks and prevention and control measures are as follows:

| Potential risks | Main causes | Prevention nd control measures |

| Electric leakage and shock |

1. Poor quality products with insufficient insulation layer thickness and unqualified materials (such as using recycled plastics); 2. The insulation layer is scratched by sharp objects during installation; 3. After long-term use, the insulation layer ages and is damaged. |

1. When making a purchase, identify "3C certified" or "CE certified" products and require the merchant to provide an insulation test report; 2. Installation should be carried out by professional personnel to avoid drilling holes or nailing on the surface of the heating film; 3. Regular inspection (once a year), if insulation layer damage is found, it should be stopped immediately. |

| Local overheating |

1. Defects in the formula of temperature limiting materials for non-standard products, resulting in ineffective temperature regulation; 2. The surface of the heating film is covered with heavy objects (such as sofas, mattresses), and the heat cannot be dissipated. |

1. Refuse the "three no products" and choose products with brand endorsement (such as companies specializing in electric heating materials); 2. When using, avoid covering hot areas to ensure smooth heat dissipation (especially in underfloor heating applications, thick carpets should not be laid on the ground). |

|

Overload circuit |

1.When multiple sets of heating membranes are connected in parallel, the total power exceeds the line's carrying capacity; 2. The parameters of the matched temperature controller and leakage protector do not match. |

1. Before installation, calculate the total power (power of each heating film multiplied by quantity) to ensure that the wire diameter meets the requirements (such as 2.5mm ² copper wire can carry up to 3000W); 2. The temperature controller should be selected as the "self limiting special type", and the rated current of the leakage protector should match the total power. |

4、 Summary: The Key to Safety Lies in "Choosing the Right Product+Standardized Use"

The technical principle of self limiting carbon fiber heating film determines that its inherent safety is higher than that of ordinary heating film, but "safety" is not absolute and two prerequisites must be met:

- Choosing the right product: Reject low-priced and inferior products, and prioritize selecting legitimate products that have passed international electrical safety certification and have clear self limiting temperature thresholds (matching the usage scenario, such as floor heating recommended at 40-50 ℃ and hot compress recommended at 50-60 ℃);

- Standardized process: Installed by a qualified team (especially when embedded in walls or floors), used according to the instructions, and regularly checked for circuit and insulation status.

As long as these two points are well done, the self limiting carbon fiber heating film can maximize its energy-saving and flexible advantages while minimizing safety risks, making it suitable for various scenarios such as homes and commercial places.

How to check whether the heating effect meets the standard when inspecting heating cables

2025-11-111、 Core testing indicators and operating methods

1.Heating rate detection: Verify whether the heating efficiency meets the standard

The heating rate directly reflects the power matching degree and heat transfer efficiency of the heating cable, and needs to be tested in a standard environment.

Testing premise

- Turn off other indoor heat sources (such as air conditioning and heating), keep doors and windows closed, and stabilize the initial room temperature at 18 ℃~22 ℃ (simulating daily use environment);

- Ensure that the heating cable is powered on normally and the temperature controller is set to the target temperature (such as 28 ℃ for ground heating and 50 ℃ for pipeline insulation).

operating steps

- Using high-precision thermometers (accuracy ± 0.1 ℃) or infrared thermometers, select three representative measuring points in the heating area (such as the center of the room, 1m away from the wall, and corners for ground heating); Pipeline insulation should be selected at areas with dense cable winding, in the middle, and at the end;

- Record the initial temperature (before power on), and record the temperature of each measuring point every 10 minutes after power on until the temperature stabilizes (continuous temperature fluctuation ≤ 0.5 ℃ for 30 minutes);

- Calculate the time from the initial temperature to the target temperature and compare it with the standard requirements.

compliance standard

- Ground radiation heating scenario: heating time ≤ 1 hour (from 20 ℃ to 28 ℃);

- Pipeline insulation scenario: The heating time must meet the design requirements (such as from 10 ℃ to 50 ℃, with a time of ≤ 2 hours, subject to the specific design documents);

- If the heating rate is too slow (such as exceeding 2 hours), it is necessary to check whether the cable power is insufficient, whether the insulation layer is damaged (heat loss), or whether the cable spacing is too large.

2. Temperature uniformity detection: Verify whether the heat distribution is balanced

Temperature uniformity should avoid local overheating or insufficient temperature, and cover the entire heating area. Infrared thermography is commonly used for visual detection.

Testing premise

- The heating cable has been running stably for more than 2 hours, ensuring sufficient heat transfer;

- Ground heating scenarios require the completion of filling layer construction (such as cement mortar layer) to avoid direct detection of cable surfaces (which may cause errors due to local contact).

operating steps

- Ground heating: Use an infrared thermal imaging device (resolution ≥ 320 × 240) to scan the entire heating area, select measurement points according to a 2m × 2m grid, and cover at least 9 measurement points (such as a 3x3 grid, including corners, edges, and centers);

- Pipeline insulation: Select a measuring point every 1m along the axial direction of the pipeline, measure the temperature at each point in four directions: up, down, left, and right of the pipeline, and record the temperature at each point;

- Calculate the difference between the highest and lowest temperatures of all measuring points to determine if they meet the standards.

compliance standard

- Ground heating: The temperature difference between all measuring points is ≤ 3 ℃ (such as 28 ℃ in the center and no less than 25 ℃ at the edges);

- Pipeline insulation: The temperature difference between measuring points on the same section is ≤ 5 ℃, and the temperature difference between adjacent measuring points in the axial direction is ≤ 3 ℃;

- If the local temperature difference is too large (such as the temperature in the corner being 5 ℃ lower than the center), it is necessary to check whether the cable spacing is uneven (locally too sparse), whether there are gaps in the insulation layer (heat loss), or whether the thickness of the pipeline insulation layer is insufficient.

3. Temperature control accuracy testing: Verify the linkage effect between the temperature controller and the cable

The temperature control accuracy ensures that the system can stably maintain the set temperature, avoiding frequent start stop or temperature drift.

Testing premise

- The temperature controller has completed parameter settings (such as setting a temperature of 28 ℃ with a return difference of 1 ℃), and it is linked normally with the heating cable;

- Use third-party high-precision temperature measuring equipment (such as platinum resistance thermometers with an accuracy of ± 0.1 ℃) to avoid relying on the built-in display of the thermostat (which may have errors).

operating steps

- Fix the high-precision thermometer probe in the center of the heating area (ground heating buried in the filling layer, pipeline insulation attached to the surface of the pipeline), with a distance of ≥ 50cm from the temperature controller sensor (to avoid mutual interference);

- Record the temperature displayed by the thermostat and the actual temperature measured by a third-party device, monitor continuously for 4 hours, and record data every 30 minutes;

- Calculate the difference between the displayed temperature and the measured temperature for each record, and calculate the maximum error.

compliance standard

- Temperature control accuracy error ≤ ± 1 ℃ (if the thermostat displays 28 ℃, the measured temperature should be between 27 ℃ and 29 ℃);

- If the error exceeds ± 2 ℃, the temperature controller sensor needs to be calibrated (such as repositioning the probe), or the signal connection between the temperature controller and the cable needs to be checked (such as poor contact of the control line).

2、 Auxiliary detection: eliminate hidden problems

1. No local overheating detection

- Purpose: To avoid local overheating caused by cable overlap or damage (leading to insulation failure);

- Operation: Use an infrared thermal imaging device to scan the cable laying area, focusing on cable joints, bends, and overlapping hidden dangers (such as the corners of ground heating);

- Standard: The local maximum temperature shall not exceed 80% of the rated temperature resistance of the cable (such as a cable with a temperature resistance of 120 ℃, the local maximum temperature ≤ 96 ℃), and shall not exceed the safe temperature of the heating object (such as the maximum temperature of the pipeline medium+10 ℃).

2. Power off cooling test (optional)

- Purpose: To verify whether the system's heat dissipation is normal and eliminate the "heat storage hazard" caused by excessive insulation layer wrapping;

- Operation: After the heating cable runs stably for 2 hours, cut off the power and record the time for each measuring point to drop from the target temperature to the initial temperature (such as from 28 ℃ to 20 ℃);

- Standard: The cooling time should meet the design expectations (if the cooling time for ground heating is ≥ 2 hours, it indicates that the insulation layer has good insulation effect; if it drops to 20 ℃ within 1 hour, it is necessary to check whether the insulation layer is damaged).

3、 Testing tools and precautions

1. Essential tools (need to be calibrated and qualified)

- High precision temperature measurement equipment: infrared thermal imaging instrument (resolution ≥ 320 × 240, temperature measurement range -20 ℃~300 ℃), platinum resistance thermometer (accuracy ± 0.1 ℃);

- Timing tool: stopwatch or electronic timer (accuracy ± 1 second);

- Recording tool: Inspection Record Form (indicating the location, time, and temperature values of the measuring points, and signing for confirmation).

Precautions

- Avoid environmental interference: Close doors and windows during detection, prohibit frequent movement of personnel (to avoid air flow affecting temperature), and prohibit placing heavy objects in the heating area in ground heating scenarios (to compress the filling layer and affect heat transfer);

- Pipeline insulation needs to simulate actual working conditions: if there is a medium (such as hot water) inside the pipeline, the temperature of the medium should be kept stable (such as set at 30 ℃), and then the heating effect of the cable should be tested to avoid interference from temperature fluctuations of the medium;

- Data retention: After the testing is completed, a "Heating Effect Testing Report for Heating Cables" must be issued, accompanied by infrared thermal imaging images and temperature record sheets, as the basis for acceptance.

The core of accepting the heating effect of the heating cable is to verify it through three major indicators: heating speed, temperature uniformity, and temperature control accuracy, combined with professional tools and standard processes, while also investigating hidden problems such as local overheating and abnormal heat dissipation. If the test does not meet the standard, it is necessary to first investigate the cable power matching, laying spacing, insulation layer quality, and other issues, rectify them, and retest to ensure that the system meets safety and usage requirements.

Selection and Installation Guide for Heating Mats in Different Environments

2025-11-11Heating mats (also known as heating pads or electric heating mats) are categorized into different types based on "protection rating, heating power, and material." They must be matched to the core needs of various environments such as households, industries, and agriculture, while installation should avoid environment-specific risks (e.g., moisture, high temperatures, and heavy object compression).

Classification of Core Environment and Selection of Heating Seat

The "risk points" and "heating requirements" vary greatly in different environments, so when choosing, priority should be given to locking in "protective performance" and "power parameters" before matching materials.

1. Family environment: Focus on "safety against electric shock+low noise"

Family scenes are mainly used for bedroom (mattress heating), living room (carpet heating), and bathroom (floor insulation), with core requirements of safety, comfort, and non-interference.

Key points for selection:

- Protection level: It must reach IPX4 or above (splash proof), and the bathroom should choose IPX7 (short-term immersion) to avoid danger caused by splashing water during showering or water accumulation on the floor.

- Heating power: Choose 60-100W (single person) and 120-180W (double person) for the bedroom mattress heating seat to avoid excessive power causing dry and hot sleep; Choose 150-250W for the living room carpet heating mat to meet local heating needs.

- Material: The mattress heating mat should be made of cotton or suede surface (skin friendly and breathable), and the bathroom should be made of PVC waterproof surface (easy to clean), and it should have an "automatic temperature limit function" (automatically power off when the temperature exceeds 40 ℃).

Typical products:

- Household double waterproof electric mattress, bathroom anti slip heating floor mat.

2. Industrial environment: focus on "high temperature resistance+aging resistance"

In industrial scenarios, it is commonly used for equipment insulation (such as reaction vessels and tank outer walls), pipeline tracing (to prevent medium solidification), and local heating in workshops. The core requirements are resistance to harsh environments and long-term stable operation.

Key points for selection:

- Protection level: At least IPX5 (anti spray), IPX6 (anti strong spray) is required for outdoor or humid workshops to prevent industrial water and dust from entering.

- Heating power: For equipment insulation, choose 200-500W/㎡ (adjusted according to the solidification point of the medium, such as 300W/㎡ or more for asphalt storage tanks), and for pipeline heat tracing, choose 100-300W/m (matched according to the pipeline diameter).

- Material: The surface layer is made of silicone rubber or fluoroplastic (temperature resistance -40 ℃~200 ℃, resistant to engine oil and chemical corrosion), and the internal heating wire is made of nickel chromium alloy (anti-oxidation, with a service life of more than 10 years).

Typical products:

- Industrial silicone rubber heating mat, pipeline heat tracing heating mat.

3. Agricultural environment: focus on "moisture-proof+uniform heating"

Agricultural scenarios are mainly used for greenhouse (soil heating), seedling box (seedling insulation), and animal husbandry (such as piglet insulation and chick rearing), with core requirements of moisture resistance, uniform heating, and no damage to animals and plants.

Key points for selection:

- Protection level: IPX4 (anti dew, irrigation splash), additional PE waterproof film wrapping is required for buried soil use (to prevent soil moisture infiltration).

- Heating power: Select 80-150W/㎡ for greenhouse soil heating (maintaining soil temperature of 15-25 ℃, suitable for vegetable and flower growth); Select 50-100W seedling box (precise temperature control in small space).

- Material: The surface layer is made of aging resistant PET material (resistant to ultraviolet radiation and soil corrosion), avoiding the use of easily degradable cotton materials. The spacing between heating wires should be uniform (with an error of ≤ 2cm) to prevent local high temperature from damaging the root system.

Typical products:

- greenhouse soil heating mat, seedling box dedicated heating mat.

4. Outdoor environment: focus on "cold resistance+wind and rain resistance"

Outdoor scenes are often used for camping tents (heating), outdoor equipment (such as monitoring boxes for insulation), and pedestrian walkways (snow melting assistance), with the core requirements being resistance to low temperatures and wind and rain erosion.

Key points for selection:

- Protection grade: IPX6 and above (to prevent rainstorm and strong wind from carrying rainwater), IPX8 (buried and ponding resistant) is required for outdoor snow melting.

- Heating power: Choose 100-200W for tent heating (fast heating in small spaces, used with tent insulation layer); Select 80-150W for outdoor equipment insulation (maintain the internal temperature of the equipment at 5-10 ℃ to prevent component freezing damage).

- Material: The surface layer is made of wear-resistant Oxford cloth and waterproof coating (scratch resistant and tear resistant), with an internal insulation cotton layer (to reduce heat loss). The heating wire needs to be equipped with "low temperature start protection" (can be powered on normally at -30 ℃ to avoid abnormal resistance at low temperatures).

Typical products:

- Outdoor camping electric heating mat, outdoor equipment insulation heating mat.

General installation specifications and environment specific precautions

The core of installation is to adapt to environmental risks. Based on the general steps, protective measures need to be added for different environments to avoid safety hazards or performance failures.

1. Universal installation steps (applicable to all environments):

- Site preparation: Clean the installation surface to ensure there are no sharp foreign objects (such as nails, gravel), and avoid scratching the surface of the heating mat; If the installation surface is uneven (such as the outer wall of industrial equipment), it is necessary to use high-temperature resistant tape to level it, ensuring that the heating seat is tightly attached (reducing heat loss).

- Wiring and fixing: Connect the power supply according to the instructions of the heating seat (matching the rated voltage, 220V for household use, and 380V for industrial equipment), and seal the wiring with waterproof terminals (universal for all environments to prevent short circuits); Use heat-resistant tape or buckles to secure the heating mat and avoid displacement (especially in outdoor and industrial settings, to prevent it from falling off due to wind or equipment vibration).

- Testing and debugging: Before powering on, use a multimeter to check the resistance of the heating seat (consistent with the instructions to rule out open circuits); After powering on, run at low power for 30 minutes to check for local overheating (detected with an infrared thermometer, temperature deviation should be ≤ 5 ℃), and at the same time test whether the temperature controller (if any) starts and stops normally.

2. Special installation requirements for different environments

Family environment (bathroom/bedroom):

- The installation of the bathroom should be away from the shower area (at least 1.5 meters), the power socket should be equipped with a "splash box", and the edge of the heating seat should be 2cm above the ground (to prevent water from overflowing).

- The heating mat of the bedroom mattress cannot be folded for use (to avoid the breakage of heating wires), and heavy objects (such as heavy mattresses and suitcases) should not be pressed to prevent local temperature from being too high.

Industrial environment (equipment/pipelines):

- When installing the outer wall of the equipment, the heating mat should avoid the equipment interface and valves (to prevent scratching during operation), and an insulation layer (such as rock wool or glass wool) should be wrapped around the outside of the heating mat to reduce heat loss to the air and save more than 30% energy.

- When installing pipeline heat tracing, the heating mat needs to be spiral wound (with a spacing of 5-10cm, adjusted according to the diameter of the pipeline), and cannot overlap (overlapping areas will double the temperature and cause burning).

Agricultural environment (soil/nursery box):

- When installing underground in soil, a layer of PE waterproof film should be laid first (followed by a heating mat, and finally covered with soil). The waterproof film should extend 30cm beyond the edge of the heating mat (to prevent soil moisture from seeping in), and the soil cover thickness should not exceed 10cm (too thick will reduce thermal conductivity efficiency).

- When installing the seedling box, the heating mat should be placed in the middle position at the bottom of the box, with a layer of insulation board on top (to avoid direct heat damage to the seedling roots), and then the seedling tray should be placed.

Outdoor environment (tent/trail):

- When installing inside the tent, the heating mat should be placed above the moisture-proof mat (to avoid moisture erosion on the ground), and should not be close to flammable materials in the tent (such as canvas, down sleeping bags, at least 30cm away).

- When assisting with snow melting on outdoor trails, the heating mat should be buried 5-8cm below the trail bricks, leveled with fine sand above (and then paved with step bricks), and linked with rain and snow sensors (only activated during snowfall to avoid energy consumption).

Core avoidance points for selection and installation

- Do not blindly pursue high power: excessive power in household scenarios can easily lead to overheating and increased power consumption; Excessive power in agricultural scenarios can damage crop roots, and the power should be calculated based on the "required temperature of the environment" (such as maintaining a soil temperature of 15 ℃, selecting 80W/㎡ is sufficient).

- Do not ignore the protection level: Heating mats with IPX4 or below in the bathroom are prone to short circuits due to splashing water; Industrial outdoor use with IPX5 or below may damage internal components due to rainwater intrusion, and the correct level must be selected according to the environmental humidity.

- Do not omit testing after installation: do not check the resistance before powering on, there may be a risk of open circuit; Not testing the local temperature may lead to local overheating due to uneven adhesion, especially in industrial and outdoor scenarios, where later maintenance is difficult. Early testing can avoid more than 80% of faults.

The core advantages of electric underfloor heating over water underfloor heating

2025-11-11Among the two mainstream solutions for ground radiation heating, electric underfloor heating has differentiated advantages in multiple dimensions due to its system characteristics, user experience, and scene adaptability, especially in line with modern households' heating needs for "flexibility, peace of mind, and efficiency". Below are several key aspects that provide a detailed overview of the core advantages of electric underfloor heating over water underfloor heating:

1、 The system is simpler and the installation is more convenient

One of the core advantages of electric underfloor heating is its minimalist system architecture, which reduces complexity from components to the entire construction process

- Fewer components and no redundant equipment: Only the three core components of "heating element (heating cable/electric heating film)+temperature controller+wire" are needed, eliminating the need for complex equipment such as wall mounted boilers, water collectors, circulation pumps, expansion tanks, etc. necessary for water floor heating, reducing system failure points (water floor heating only has 10+potential maintenance nodes for pipeline interfaces and wall mounted boilers).

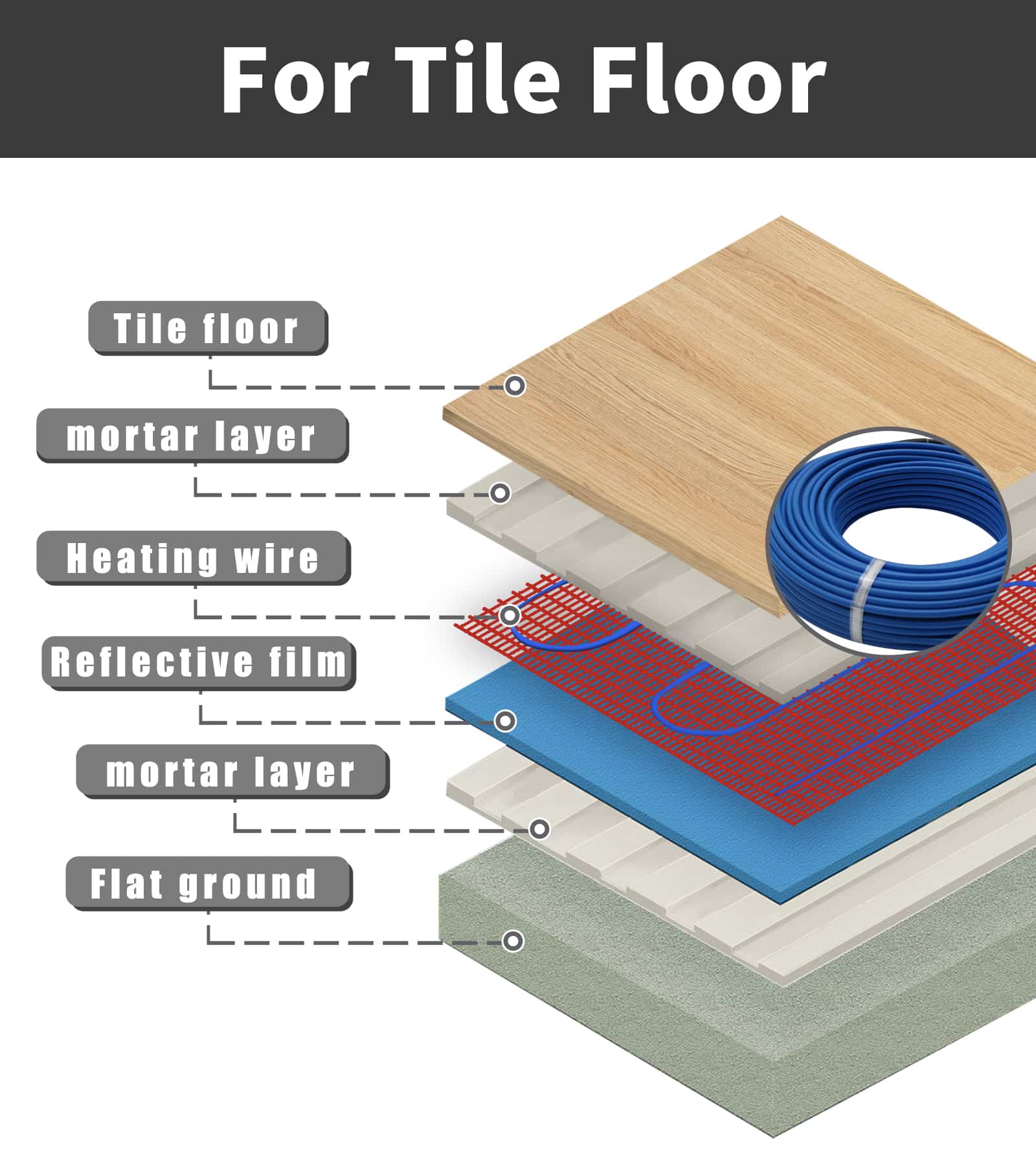

- Short construction period and minimal interference with decoration: The construction of a 100 square meter space only takes 2-3 days, with the process of "ground leveling → laying heating elements → wiring debugging", without the need for multi-stage construction such as "installation of water collectors → pipeline laying → pressure testing → ground backfilling" like water and floor heating (water and floor heating require 5-7 days), and can quickly enter the site in the later stage of hard installation, without the need for deep binding with water and electricity renovation.

- Suitable for small area/local heating: It can be installed in local spaces such as bedrooms and study rooms as needed (such as only installing electric underfloor heating in the 20 ㎡ master bedroom), without the need for "laying pipes throughout the house+matching wall mounted boilers" like water underfloor heating (when water underfloor heating is used for local heating, frequent start and stop of wall mounted boilers may not save energy), making the cost more controllable.

2、 More flexible use, more precise temperature control

Electric underfloor heating is much more flexible than water underfloor heating in terms of "temperature control" and "adaptation to usage scenarios":

- Single room independent temperature control with an error of only ± 0.5 ℃: Each room can be set to a precise temperature of 16-28 ℃ through an independent temperature controller (such as 24 ℃ in the master bedroom and 20 ℃ in the living room), while underfloor heating is affected by pipeline circulation, with a temperature difference of 1-2 ℃ between remote and nearby rooms, making it difficult to achieve local precise temperature control.

- Instant heating, no need for preheating: After turning on, the ground can heat up within 30-60 minutes and reach the set room temperature within 2-3 hours, suitable for "intermittent heating" needs (such as office workers turning off day and night, occasional use in vacation rooms); Water floor heating requires heating the cold water inside the wall mounted boiler and circulating through the pipes for 4-6 hours before reaching the standard. It still takes a long time to preheat after shutting down and restarting, resulting in serious energy waste.

- Supporting intelligent linkage for more convenient operation: mainstream electric floor heating thermostats can be connected to mobile apps to achieve remote switching and scheduled appointments (starting 1 hour before work and enjoying warmth at home), and some models can also be linked with temperature and humidity sensors for automatic adjustment; The temperature control of underfloor heating relies heavily on local settings of wall mounted boilers, with weak intelligent linkage and limited by the circulation system, resulting in slow remote adjustment response speed.

3、 Zero maintenance cost, worry free and more durable

From the perspective of long-term use, electric underfloor heating significantly reduces the "later investment" and avoids the maintenance trouble of water underfloor heating:

- Fully enclosed operation, lifetime zero maintenance: The outer layer of the heating cable is a high-temperature resistant cross-linked polyethylene insulation layer+shielding layer. After being buried in the ground, it is fully enclosed without loss. Under normal use, there is no need for "annual pipeline cleaning and wall mounted boiler maintenance" like water underfloor heating, which can save a lot of maintenance costs every year.

- No risk of water leakage/freeze-thaw: Thoroughly avoiding the core hidden danger of underfloor heating - pipeline freeze-thaw and aging water leakage caused by lack of drainage during winter heating shutdown (the annual probability of water leakage for underfloor heating is about 10%, and maintenance requires breaking the ground, increasing costs); Electric underfloor heating only needs to ensure proper wiring during installation, and there will be no "water related" faults in the future.

- The service life is synchronized with the building: high-quality heating cables (in accordance with GB/T 20841 standard) have a service life of 50 years, which is basically the same as the service life of building construction; Although the service life of water and floor heating pipelines can reach 50 years, wall mounted boilers only take 10-15 years, and components such as water collectors and circulation pumps need to be replaced 8-12 years, resulting in higher long-term hidden costs.

4、 Stronger energy adaptability and better environmental attributes

As a "clean energy carrier", electric underfloor heating has more advantages in energy compatibility than traditional gas water underfloor heating:

- The energy conversion efficiency is nearly 100%, with no energy loss: the current is directly converted into heat energy through the heating element, with an efficiency of over 99%, without pipeline heat dissipation or wall mounted boiler heat loss (the thermal efficiency of water floor heating wall mounted boilers is 85% -95%, and 5% -10% of heat is lost during pipeline transportation); Especially in small apartments or local heating, the energy-saving advantage is more obvious (when using water and floor heating in small areas, wall mounted boilers can be used as a "small horse pulling a big cart", and the thermal efficiency drops to below 70%).

- Adapt to peak and valley electricity prices to reduce usage costs: In areas where peak and valley electricity prices are implemented, electric underfloor heating can be set to a "valley section heat storage, peak section insulation" mode. Low price electric heating for ground heat storage at night requires only a small amount of electricity to maintain temperature during the day, and the winter usage cost is 20% -30% lower than that of water underfloor heating.

5、 No noise interference, more comfortable living experience

Electric underfloor heating solves some of the pain points of water underfloor heating in terms of "silence" and "body sensation adaptation":

- Zero operating noise, suitable for sensitive populations: electric underfloor heating without circulating pumps, wall mounted boilers and other moving parts, completely silent during operation; The wall mounted boiler for underfloor heating generates 40-50 decibels of noise during operation (similar to household fans), and the circulating pump may also produce low-frequency noise, which has a significant impact on the elderly, children, or sleep sensitive populations.

- More uniform thermal radiation to avoid "head hot and feet cold": The heating cable is evenly laid on the ground and heated by far-infrared radiation, and the heat is evenly spread upwards from the ground, in line with the ergonomic temperature field of "feet warm and head cold" (ground temperature 28-32 ℃, top temperature 18-22 ℃); Water floor heating is affected by the spacing between pipelines and water flow velocity, which may result in local temperature unevenness (such as heat near pipelines and cooling in gaps), especially in large spaces.

- Not affecting indoor humidity and avoiding dryness: The heating process of electric underfloor heating does not consume moisture in the air, and the indoor relative humidity can be maintained at 40% -60% (comfortable range); Partial gas water underfloor heating may consume indoor air due to the combustion of wall mounted boilers. Insufficient ventilation may cause humidity to drop below 30%, requiring the use of an additional humidifier.

The selection of electric floor heating and water floor heating needs to combine their own house type, energy conditions and usage habits. However, from the perspective of "system simplification, long-term worry free, flexible adaptation", electric floor heating has become an important choice for modern light and smart homes.

What are the different usage scenarios between aluminum foil heating film and graphene heating film

2025-11-11The difference in usage scenarios between aluminum foil heating film and graphene heating film is essentially determined by their performance shortcomings and advantages - the former is limited by low cost but limited performance, while the latter relies on high performance to meet mid to high end needs. The specific scenario differentiation is as follows:

Typical usage scenarios of aluminum foil heating film: low cost, low requirements, temporary needs

1.Simple civilian heating (non long-term use)

- Low price heating pads: such as office seat heating pads and winter floor mats (non smart, no zone temperature control, only basic heating function required);

- Disposable/short-term hot compress products: such as cheap hot compress packs sold in pharmacies (single use or repeated use up to 10 times), temporary waist and abdomen warming patches (relying on the low-cost characteristics of aluminum foil to control the selling price);

- Simple home appliance auxiliary heating: such as low-end small foot warmers (low power, no need for precise temperature control), and auxiliary heating modules for inexpensive dehumidifiers (only requiring basic heating function).

2.Temporary antifreeze/heat tracing (short-term emergency)

- Temporary anti freezing measures for winter pipelines: such as rural outdoor water pipes and small water pipelines, short-term (1-3 months) wrapped with aluminum foil heating film for anti freezing (no need for long-term weather resistance, can be removed immediately after use);

- Temporary insulation for logistics transportation: When transporting fruits and vegetables for short distances in low-temperature areas, aluminum foil heating film is used as a simple insulation layer (disposable, cost priority).

3.Low end industrial auxiliary (non core heating)

- Local insulation for small equipment: such as edge auxiliary heating for low-end ovens (core heating relies on other components, and aluminum foil only serves as a supplement);

- Temporary construction heating: Short term heating and curing of cement during construction (no precise temperature control required, disposable after use).

Typical application scenarios of graphene heating film: high performance, long lifespan, high safety requirements

1.Smart wearables and consumer electronics (requiring lightweight, secure, and flexible)

- Heating wearable devices: such as heating scarves and ski suits with built-in heating elements (which need to be lightweight and fit the body, and powered by 5V USB to avoid electric shock. The rigidity and high voltage risk of aluminum foil cannot be met);

- Intelligent heating accessories: such as gaming chair heating module (requiring long-term use+zone temperature control), baby constant temperature sleeping bag (requiring low voltage safety+uniform heating to prevent burns).

2.New energy vehicles and transportation (requiring high efficiency, safety, and long lifespan)

- Car seat heating: New energy vehicle seats must use graphene (aluminum foil consumes a lot of electricity and can cause safety hazards due to local overheating, graphene can be used in conjunction with battery low-voltage power supply and has a lifespan synchronized with the car);

- Battery thermal management: Heating of electric vehicle batteries in low-temperature areas (requires rapid and uniform heating to reduce energy consumption, low efficiency of aluminum foil will increase range loss).

3.Architecture and Home Furnishings (requiring durability, energy efficiency, and space adaptation)

- Ultra thin underfloor heating: underfloor heating for renovated rooms and old houses (with a graphene film thickness of only 0.1-0.3mm, which can be laid under the floor without raising the ground); Aluminum foil film is thick and has a short lifespan, making it unsuitable for long-term buried use;

- Intelligent temperature controlled furniture: such as temperature controlled mattresses (requiring zone temperature control and noise reduction, unable to adapt to the stiffness and noise of aluminum foil).

4.Medical and Health (requiring biocompatibility and precise temperature control)

- Far infrared therapy equipment: such as knee pads and lumbar supports (graphene releases 6-14 μ m far-infrared radiation that resonates with the human body, aluminum foil does not have this characteristic, and uneven heating can easily cause burns);

- Medical insulation blanket: Postoperative insulation for ICU patients (requiring low pressure safety and precise temperature control ± 0.5 ℃, aluminum foil cannot meet the accuracy).