Floor heating mat industry standards and certification

2024-11-25With the rapid development of the floor heating mat industry, the importance of industry standards and certification systems has become increasingly prominent, they not only ensure the quality and safety of products, but also promote the healthy and orderly development of the entire industry.

The standard development of the floor heating mat industry involves many aspects, including key indicators such as electrical safety, thermal efficiency, environmental performance and service life of the product. These standards are designed to ensure that consumers can use products that are both safe and efficient, and for manufacturers, these standards have become an important reference in their development and production processes.

As an effective guarantee for the implementation of standards, the certification system sets a threshold for the market access of floor heating products. At present, the generally recognized certifications in the floor heating mat industry include but are not limited to CE certification, ROHS certification and ISO quality management system certification. The existence of these certifications makes every product that flows to the market go through strict quality testing and evaluation, which greatly reduces the risk caused by product quality problems.

In addition to the above certification, some special certifications specifically for floor heating products have also begun to appear, such as certification on electromagnetic radiation, and certification on environmental protection and harmlessness of materials. These more specialized certifications further refine the evaluation criteria of the products, making the floor heating products better meet the needs of consumers in specific fields.

Looking to the future, the standards and certification of the floor heating mat industry will continue to play an important role in regulating the development of the industry and ensuring product quality and safety. Through continuous optimization and improvement, I believe that this industry can continue to develop in the direction of more professional, environmental protection and advanced technology, and bring more warmth and comfort to people's home life. All this is inseparable from the joint efforts of every industry practitioner and the unremitting pursuit of excellent quality.

Material and installation of floor heating pad

2024-11-25As an important facility to enhance living comfort in modern homes, the material selection and installation process have a decisive impact on the final use effect. In many families pay more and more attention to the quality of life today, it is particularly important to understand the production materials and installation steps of the floor heating pad.

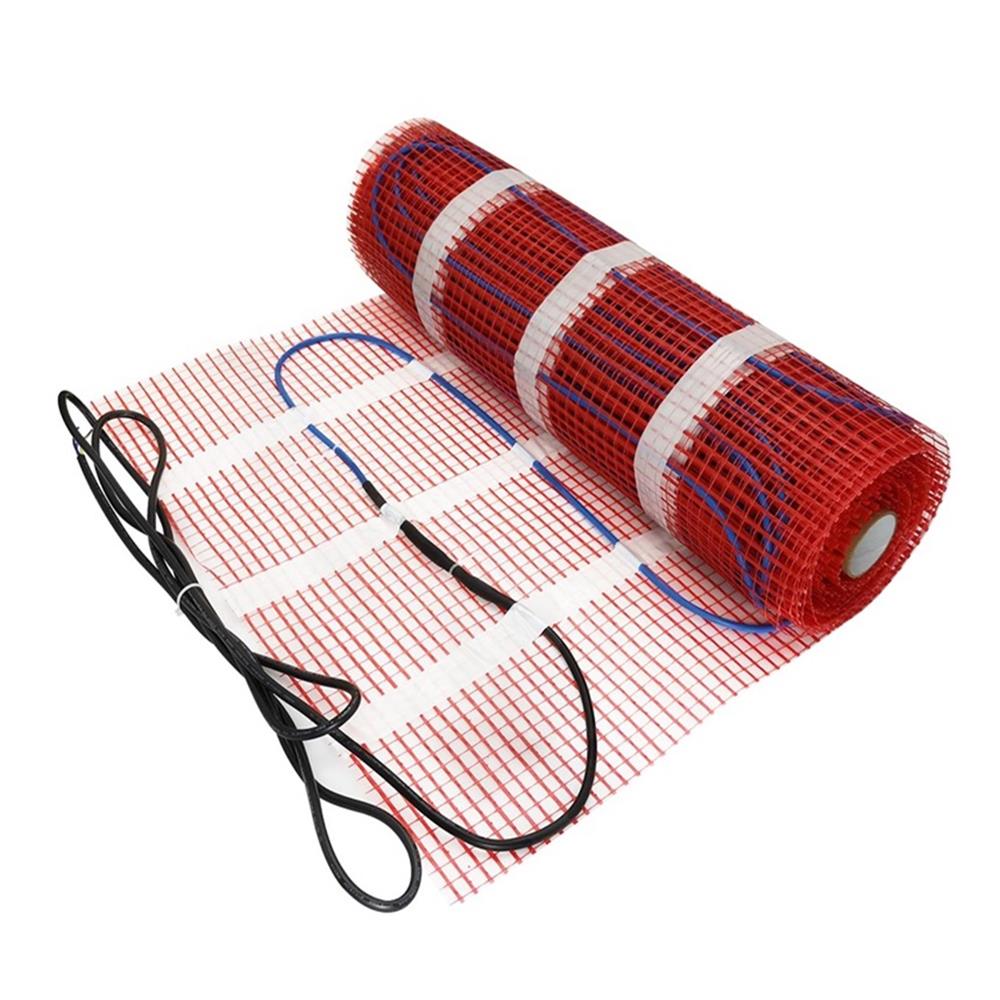

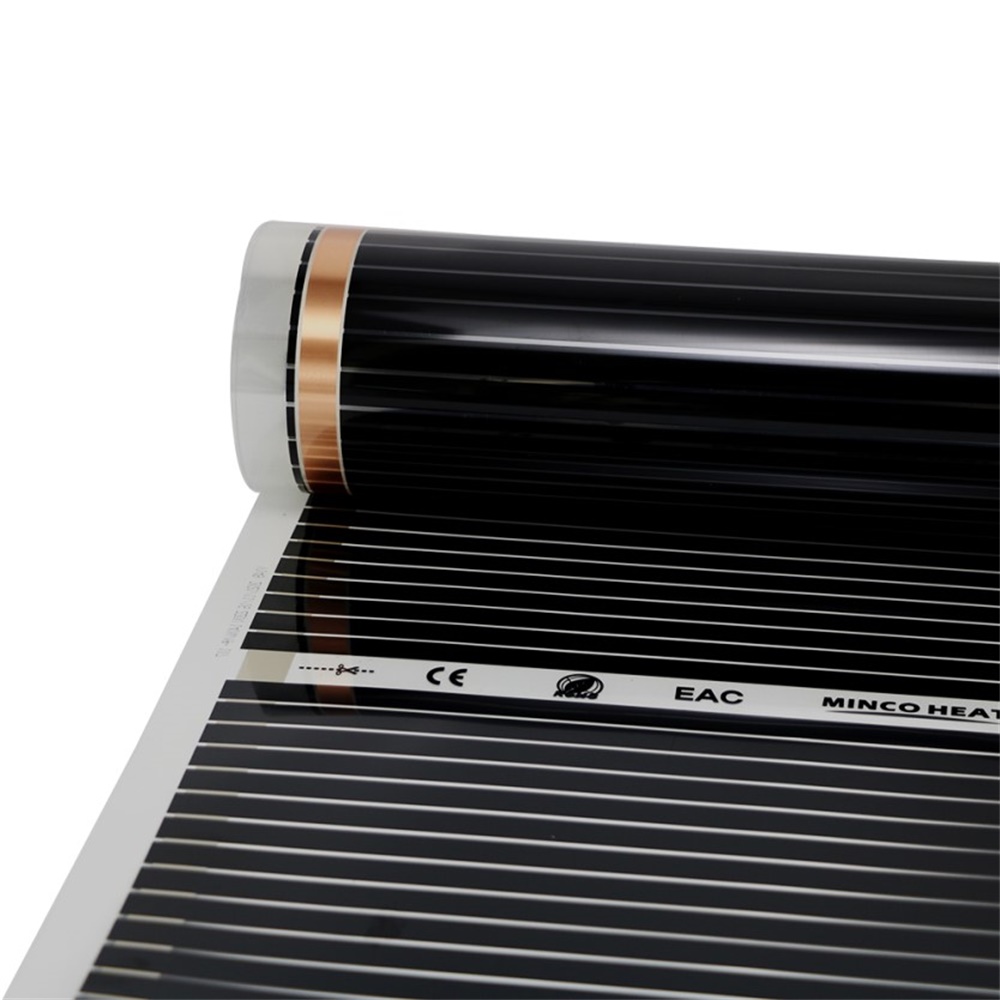

Floor heating pads are usually composed of conductive ink, graphene and insulating materials. As a special formula of silver oil, conductive ink not only has good electrical conductivity, but also has excellent adhesion and ductility, which ensures that the floor heating pad can evenly transfer heat during the heating process. Graphene, as a new material, has been widely used in the manufacture of floor heating MATS for its excellent thermal conductivity and stable chemical properties. Insulating materials are used to ensure the safety of use and prevent current leakage, common plastic materials such as PVC and PET.

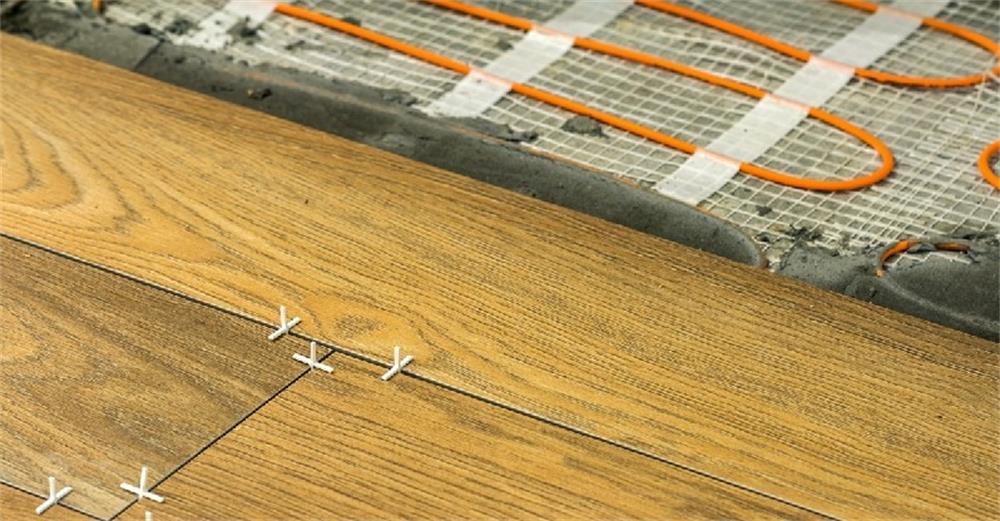

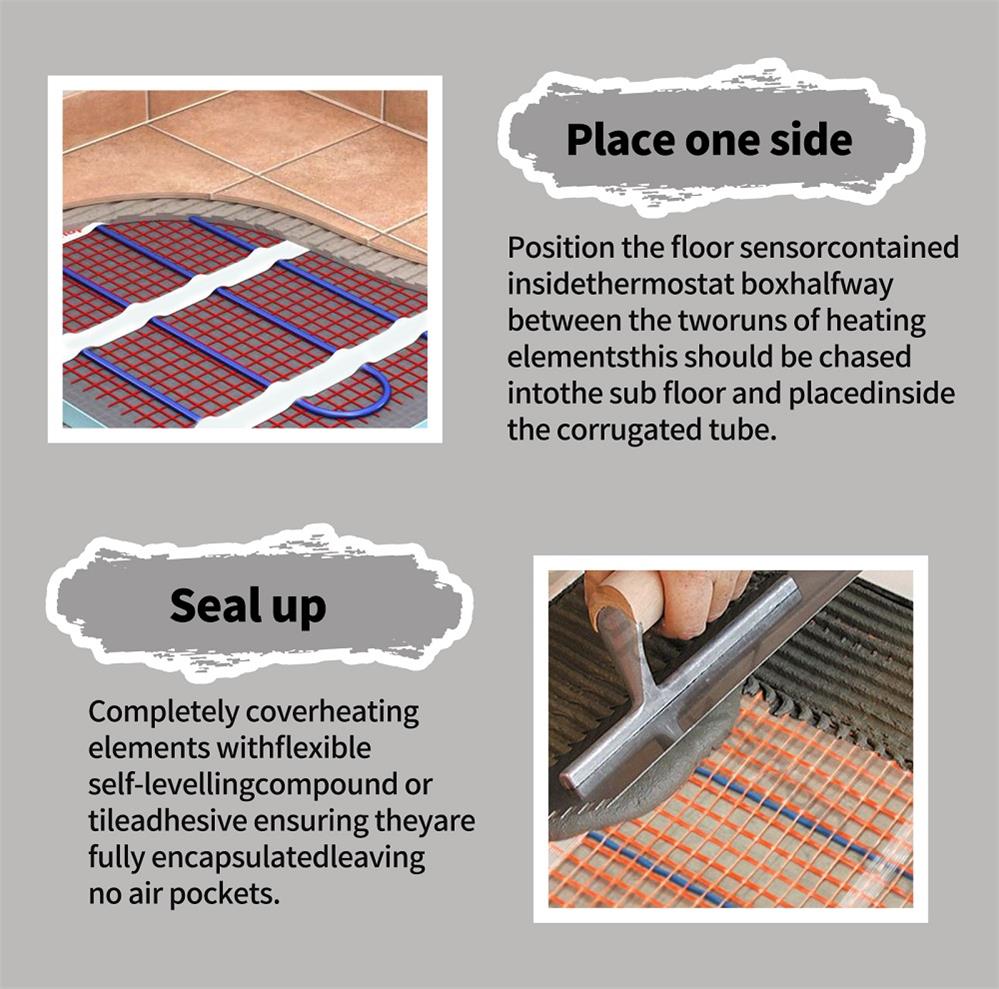

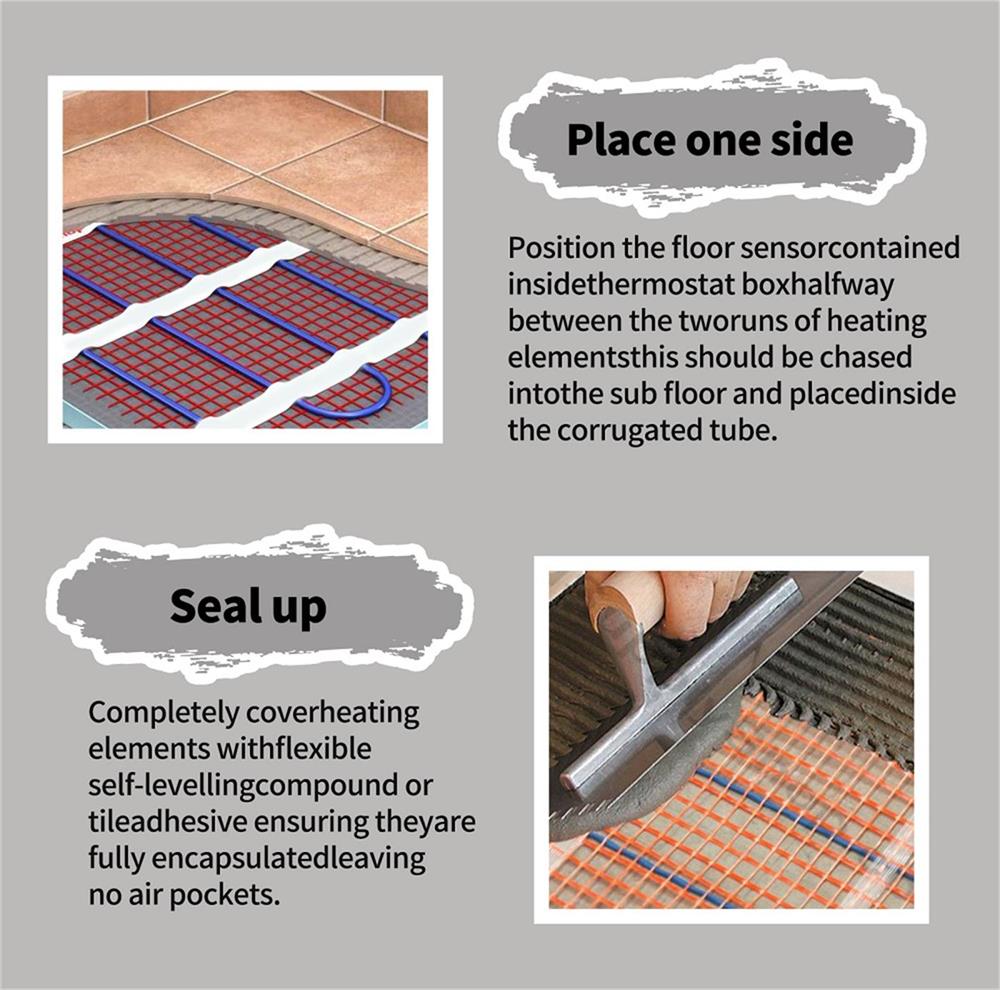

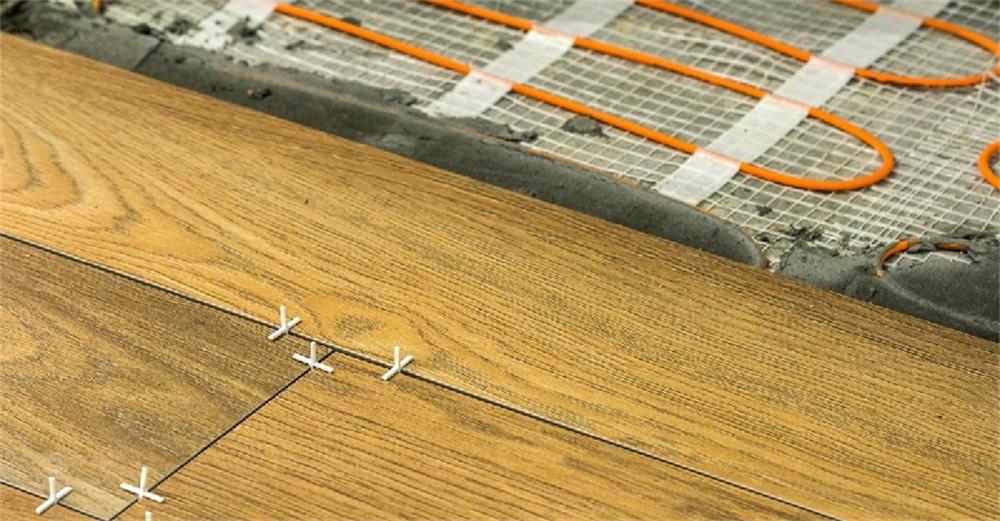

The process of installing underfloor heating is also crucial. The preparation before installation cannot be ignored. First, ensure that the floor of the room to be installed is smooth and clean, free of dust and water stains. Measure the specific size of the ground to determine the laying scheme of the floor heating pad. The next steps are specific installation steps. Lay the floor heating pad flat on the cleaned ground to ensure seamless docking between the MATS so as not to affect the heating effect. When connecting the power supply, you must follow the instructions of the product or professional electricians to ensure that the wiring is correct and the appropriate wire specifications are used. Debug the floor heating pad, adjust to the appropriate temperature, check whether the operation is normal, you can start to use after this step is completed.

It is worth mentioning that the maintenance of the floor heating pad is equally important. Regularly clean the dust on the surface of the floor heating pad to avoid sharp objects scratching the surface of the mat, these details will affect the service life and heating effect of the floor heating pad.

The production material of the floor heating pad determines its heating performance and service life, and the standardized installation process is the premise to ensure the normal operation of the floor heating pad. Through the understanding of the floor heating pad material and the correct installation and use, people can enjoy a warm and comfortable living environment in the cold season.

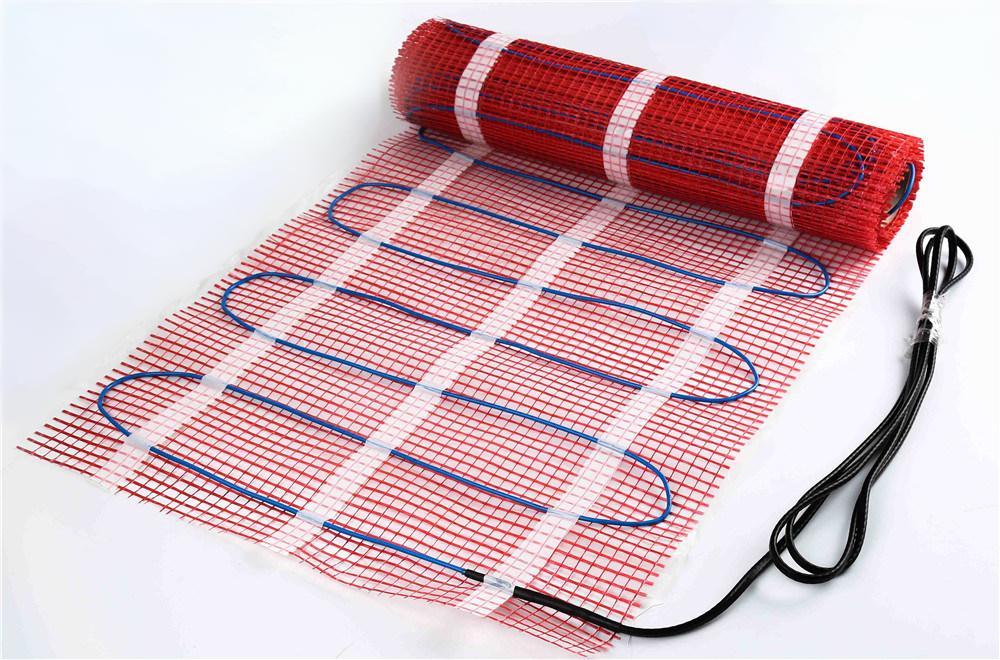

More Popular New Warming Floor Heating System - Electric Floor Heating Mat

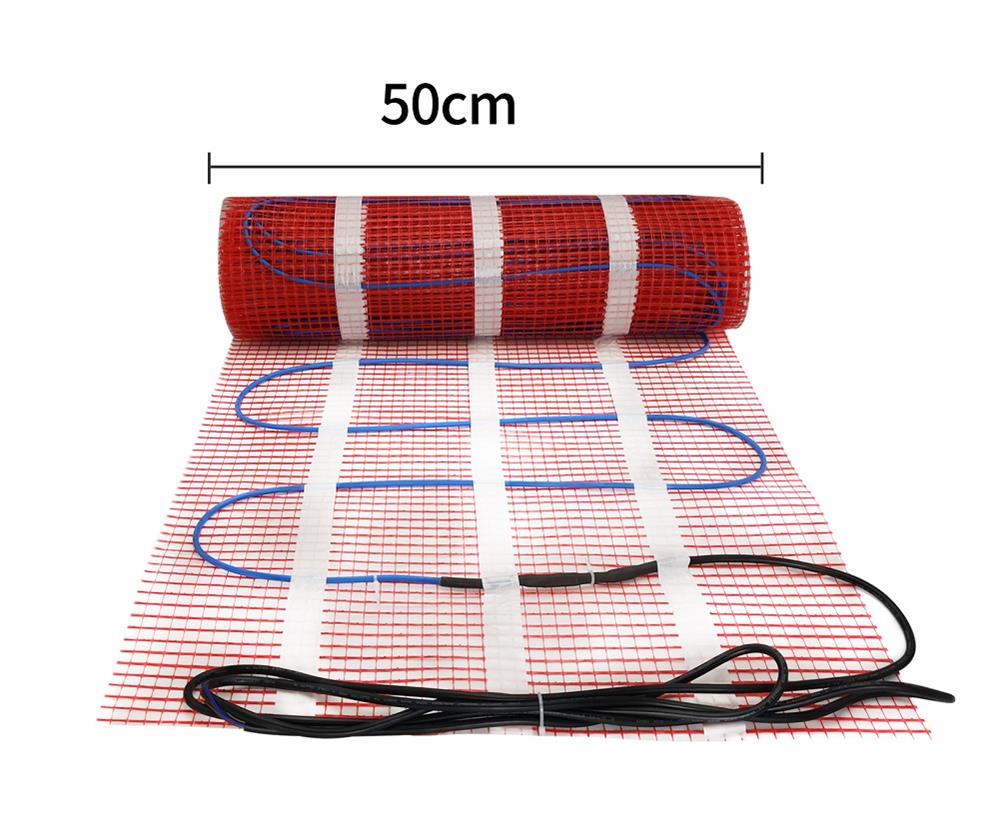

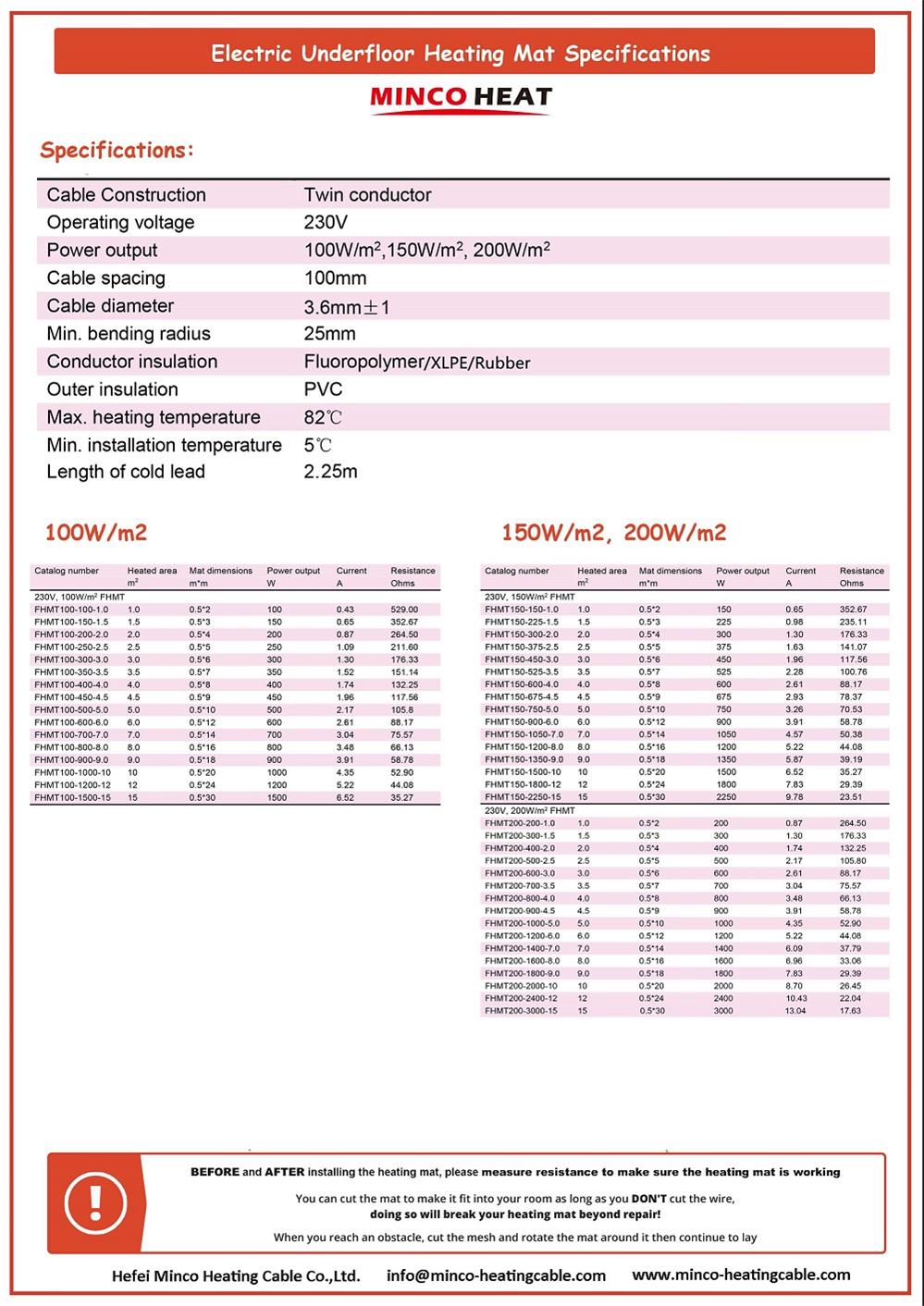

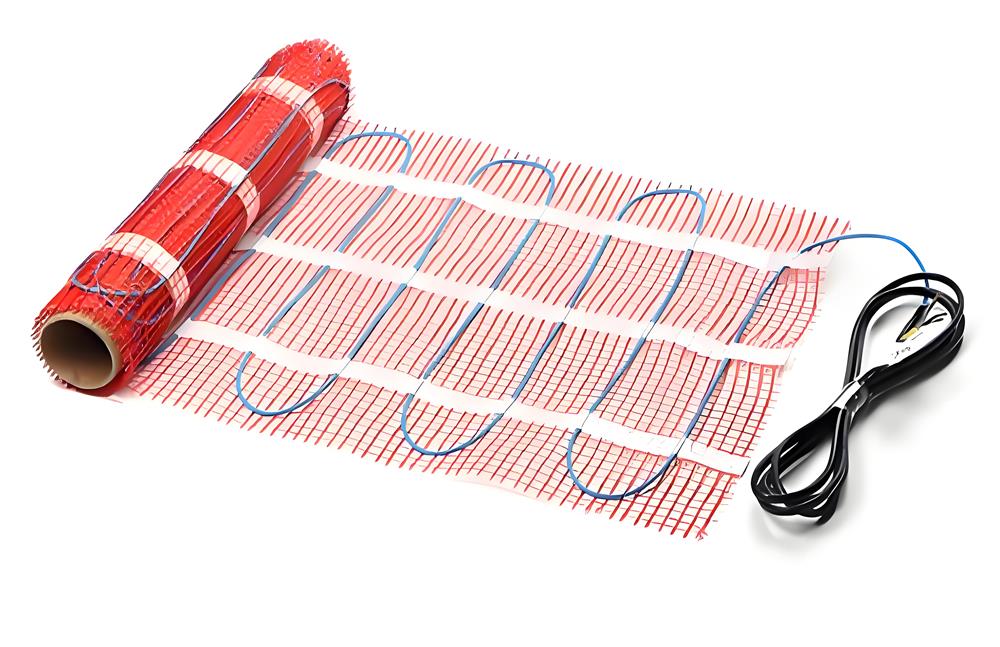

2024-11-25Product Description: Working voltage 220V, customizable. Output power typically 150W/m2, can be customized to different power levels.

Electric floor heating offers a range of benefits including comfort, energy efficiency, environmental friendliness, flexibility, stable heating, even distribution of heat, and no impact on aesthetics.

Comfort: Electric floor heating emits heat from the ground, providing warmth to the lower body, which aligns with the body's natural physiology and creates a comfortable indoor environment.

Energy Efficiency: Electric floor heating utilizes electric power for heating, eliminating the need for burning fuels and reducing the emission of smoke and harmful gases. It also allows for better control of room temperature, leading to energy savings.

Environmental Friendliness: Electric floor heating produces no smoke or harmful gases, making it an eco-friendly heating solution.

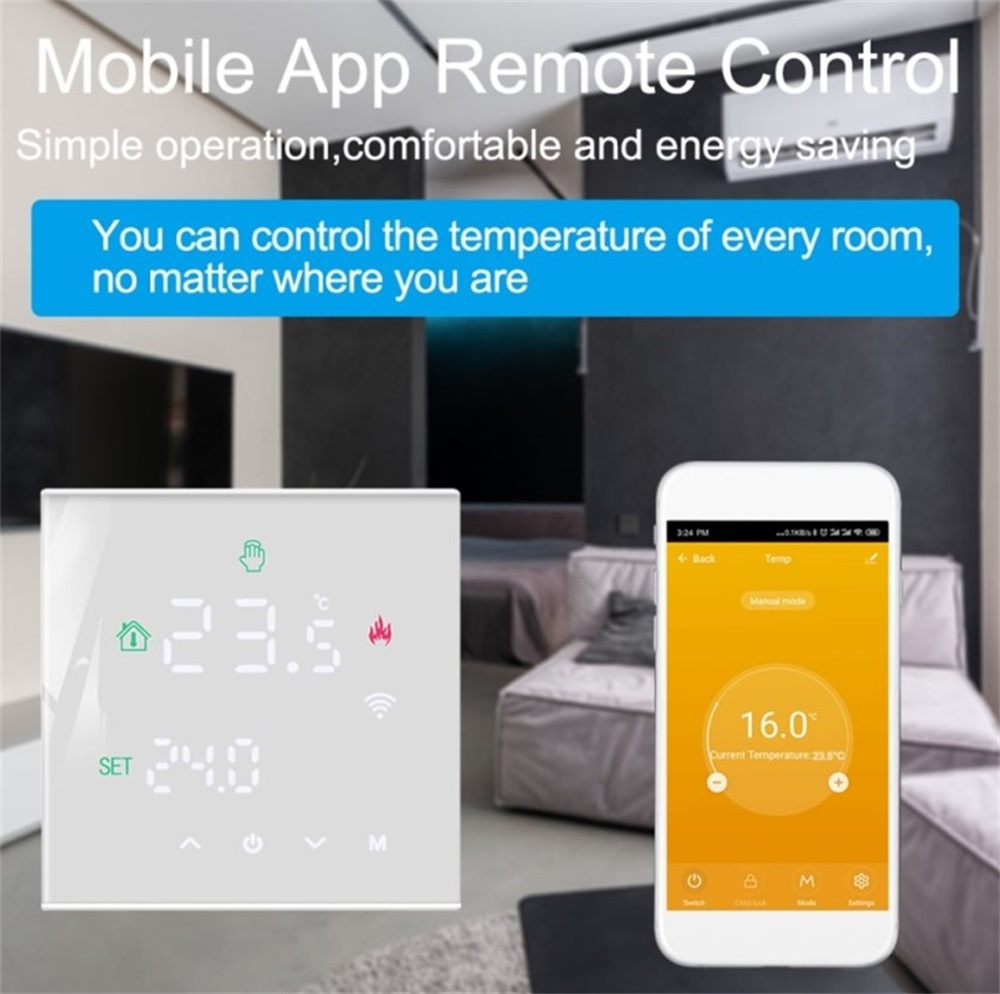

Flexibility: Installation of electric floor heating is quick and simple, without the need for extensive pipework and boiler installation. Temperature control is highly convenient, with options for smart thermostats or remote control through a mobile app.

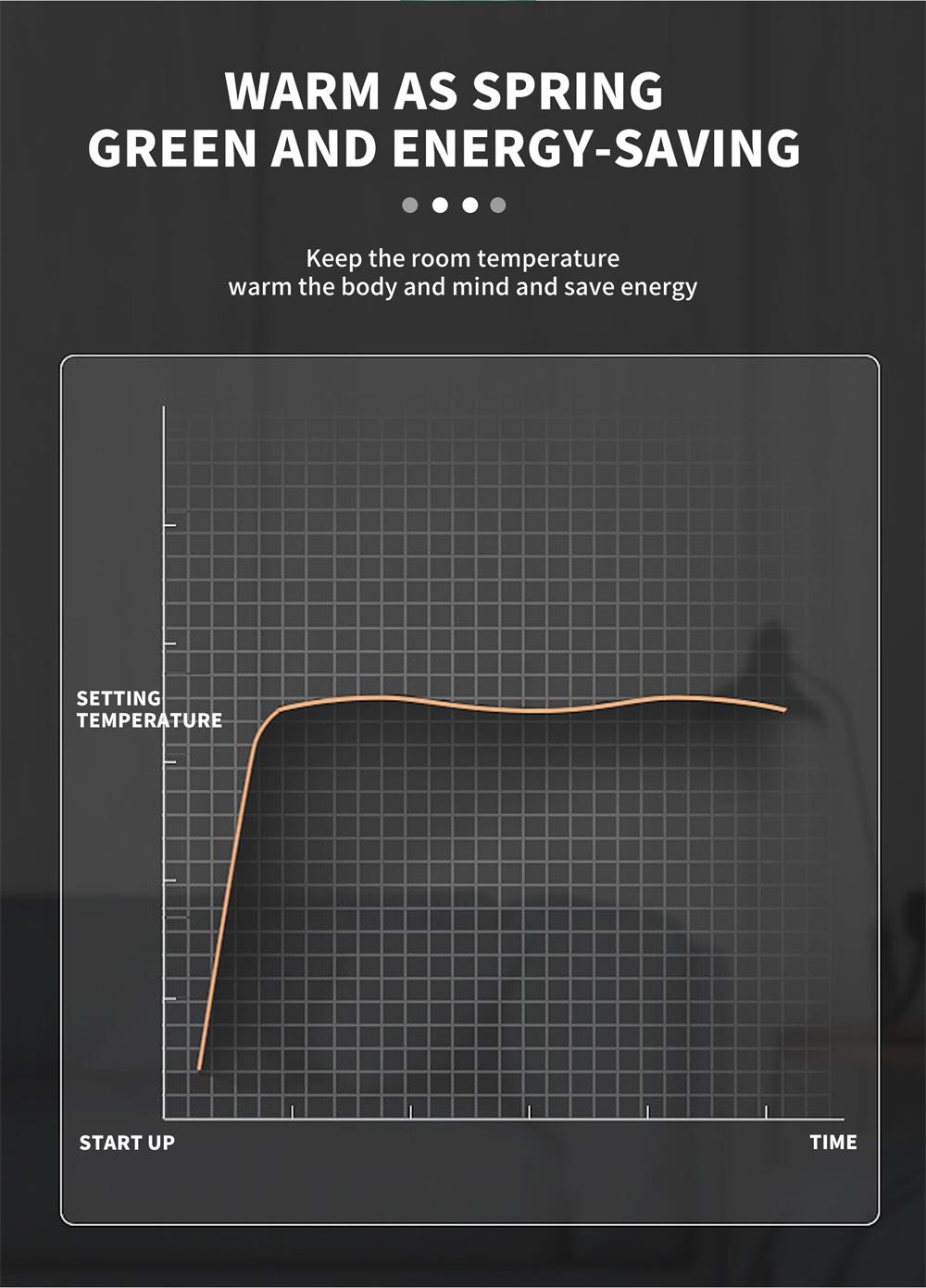

Stable Heating: Electric floor heating offers excellent heat storage capabilities, maintaining a certain level of warmth even during short interruptions in heating, preventing rapid temperature drops.

Even Distribution of Heat: Electric floor heating operates silently, providing even heat distribution throughout the room. There are no uneven hot or cold spots, ensuring a consistently pleasant indoor environment.

Aesthetically Pleasing: Electric floor heating is installed beneath the floor, preserving valuable indoor space while maintaining the overall aesthetics of the room.

Experience the ultimate comfort and energy-efficient warmth with the Electric Heating Floor Heating Pad. Upgrade your living space with this customizable heating solution that not only delivers consistent heat but also promotes a sustainable and visually appealing environment.

Potential benefits of floor heating pads in different climates and regions

2024-11-25As a modern home comfort device, the potential benefits of floor heating pads in different climates and regions are manifold. Here's some analysis:

Cold areas

1. Energy saving and environmental protection: in cold areas, floor heating pads can be used as the main or auxiliary heat source, reducing the dependence on traditional heating equipment, thereby reducing energy consumption and carbon emissions.

2. Uniform heating: The floor heating mat provides a uniform heat distribution on the ground, eliminates cold spots, improves the overall comfort, especially suitable for the elderly and children living environment.

3. Health benefits: Floor heating pads help reduce joint pain and respiratory diseases common in winter because they avoid the spread of dust and germs brought by air flow.

Mild climate areas

1. Increased comfort: Even in temperate climates, there are cold days in winter. The floor heating pad can provide a constant temperature, making the living environment more comfortable.

2. Save space: Because the floor heating pad is installed under the floor, it will not occupy the indoor space, and maintain the beautiful and spacious indoor.

3. Increase the value of the property: A home with floor heating may increase the market value of the property due to its added comfort and modern feel.

Tropical climate areas

1. Moisture-proof effect: In tropical climates, floor heating pads can be used in the rainy season or wet season to help keep the ground dry and prevent mold growth.

2. Energy-saving building integration: When designing energy-saving buildings, underfloor heating MATS can be combined with other energy-saving technologies, such as solar power generation, to provide sustainable energy solutions for the building.

High altitude areas

1. Effective heating: In high altitude areas, where the temperature is low, the floor heating pad can provide effective heating, especially in winter and at night.

2. Reduce dependence on fossil fuels: High altitude areas may lack traditional energy supplies, and underfloor heating pads can use renewable energy sources, such as geothermal or solar energy, to reduce dependence on fossil fuels.

3. Protect the structure: The floor heating pad can help protect the building structure from the impact of extreme low temperatures and extend the service life of the building.

To sum up, floor heating pads have their own unique potential benefits in different climates and regions, from enhanced comfort to energy savings to increased property value, and are adaptable and a home comfort solution worth considering.

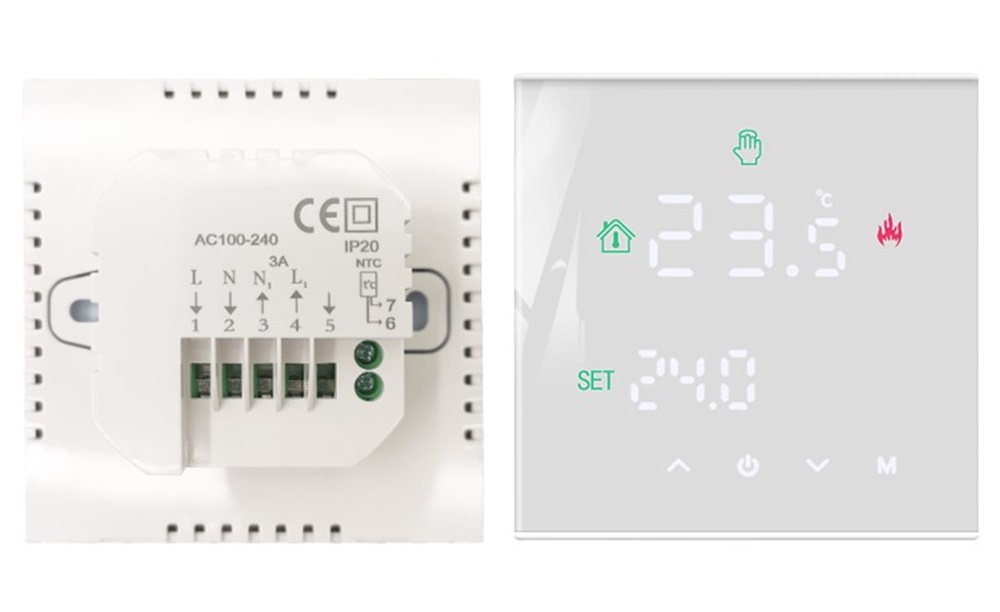

Smart Wi-Fi thermostat instructions

2024-11-25With the increasing popularity of smart home devices today, smart Wi-Fi thermostats are favored by the majority of users for their convenient remote control and accurate temperature management. This article aims to detail the use of smart Wi-Fi thermostat to help users fully tap and enjoy the convenience and comfort brought by this technology.

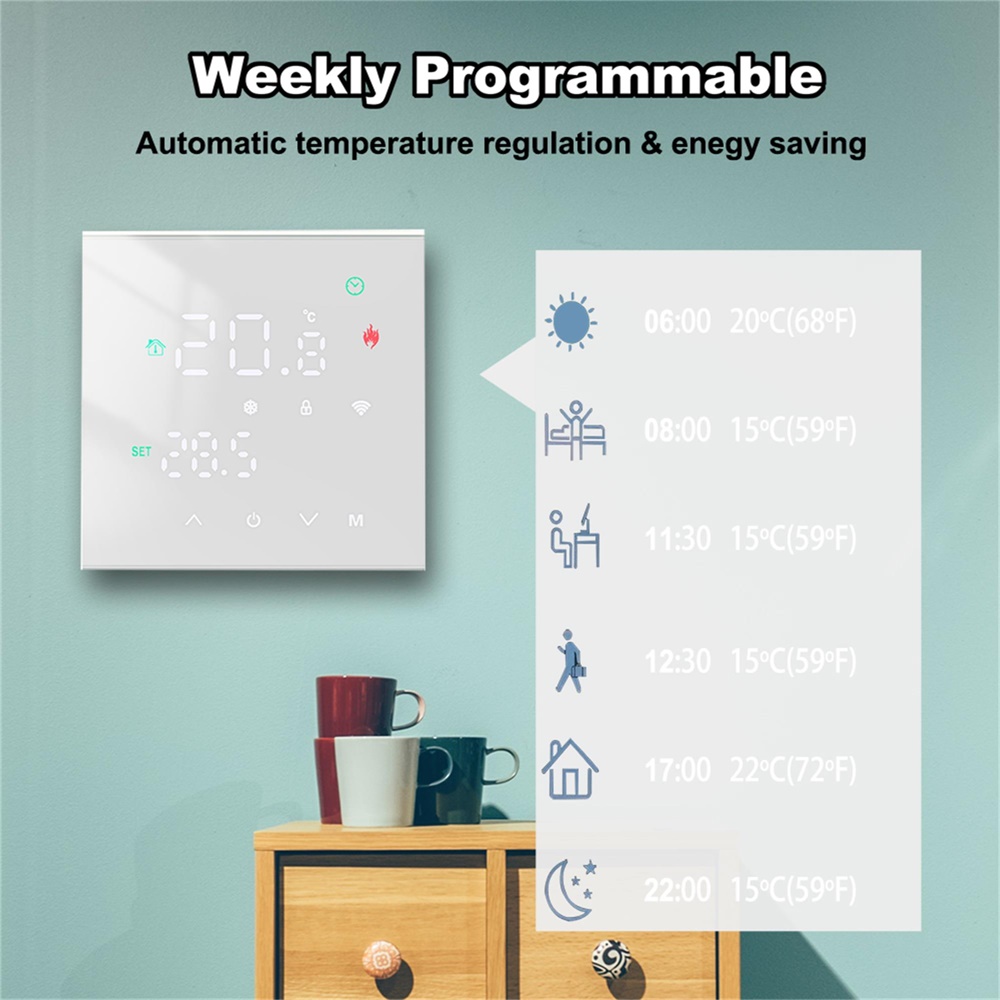

A smart Wi-Fi thermostat is a temperature control device that can be remotely connected and controlled via a Wi-Fi network. It can not only realize the temperature adjustment function of the traditional thermostat, but also remotely controlled through the Internet, real-time monitoring of the temperature status of the home, and even automatically adjust the temperature according to the user's living habits, in order to achieve the effect of energy saving and emission reduction.

After clarifying the basic working principle of the smart Wi-Fi thermostat, let's explore its specific use. Initial setup is a key step in using a smart Wi-Fi thermostat. Users need to connect the thermostat to their home Wi-Fi network. This process usually requires selecting the "Add Network" option on the thermostat's interface and following the prompts to enter the network name and password for your home Wi-Fi. After completing the network connection, the thermostat has the basic conditions for remote control.

Then, install the appropriate application. The smart Wi-Fi thermostat brands on the market usually come with their own application software to achieve full control of the thermostat from the phone or tablet. Download the app according to the accompanying instructions, and simply register and log in, so users can begin to enjoy the convenience of technology.

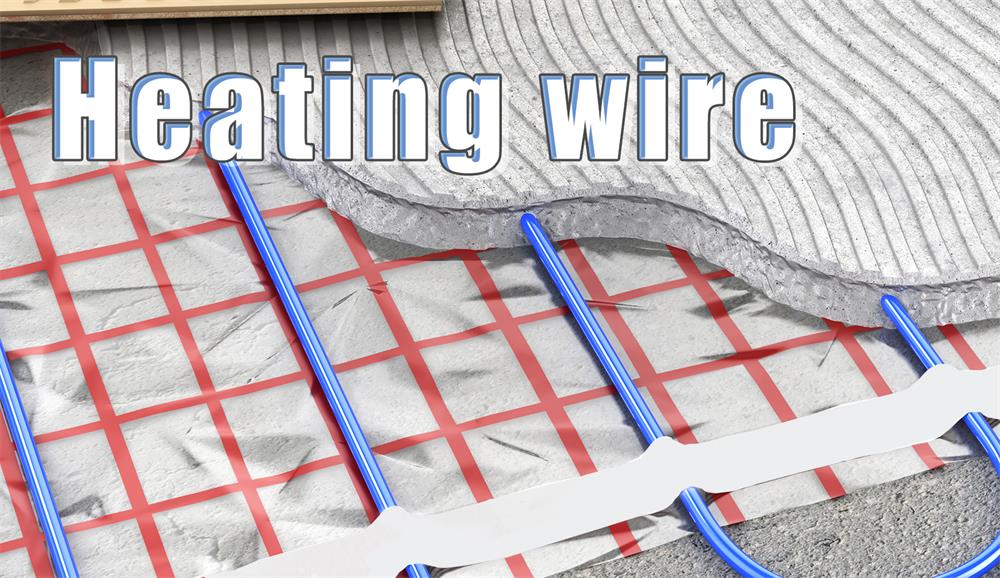

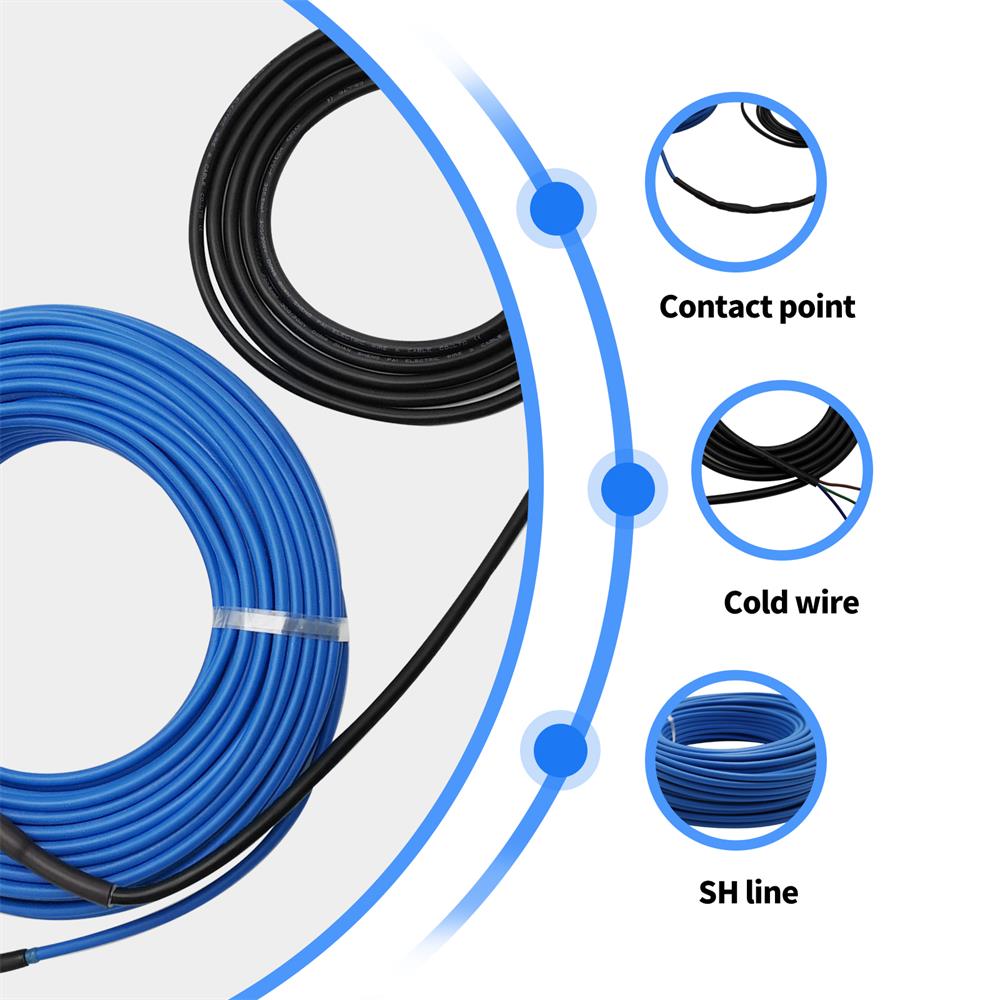

The art and science of floor heating wire

2024-11-25In the cold winter, as an efficient and comfortable heating method, the floor heating system is more and more favored by modern families. However, the performance and efficiency of an underfloor heating system depends largely on the correct installation and optimization of its gasket lines. This paper aims to deeply discuss the scientific principle, key steps and optimization strategy of floor heating mat line, in order to provide professional and practical guidance for readers.

The scientific basis of the floor heating mat line mainly involves the principle of thermodynamics and material science. The second law of thermodynamics states that the heat naturally flows from the high temperature to the low temperature, and the role of the floor heating pad is to evenly distribute heat through the ground to achieve the purpose of indoor warmth. The choice of materials is related to the efficiency of heat conduction, and materials with good thermal conductivity such as polyethylene or polypropylene plastics are usually used, which can effectively conduct heat, but also have good durability and safety.

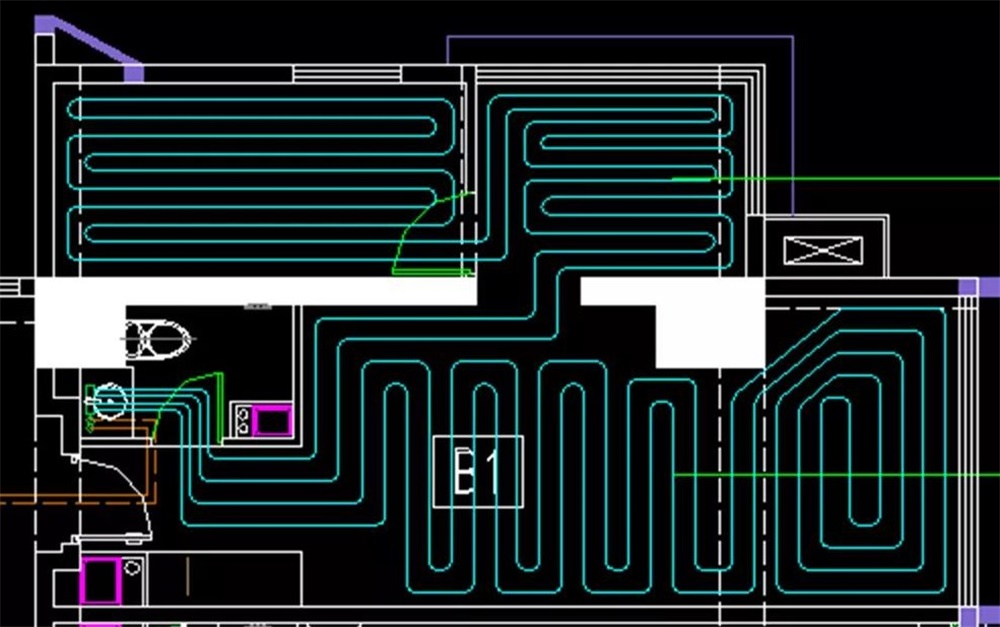

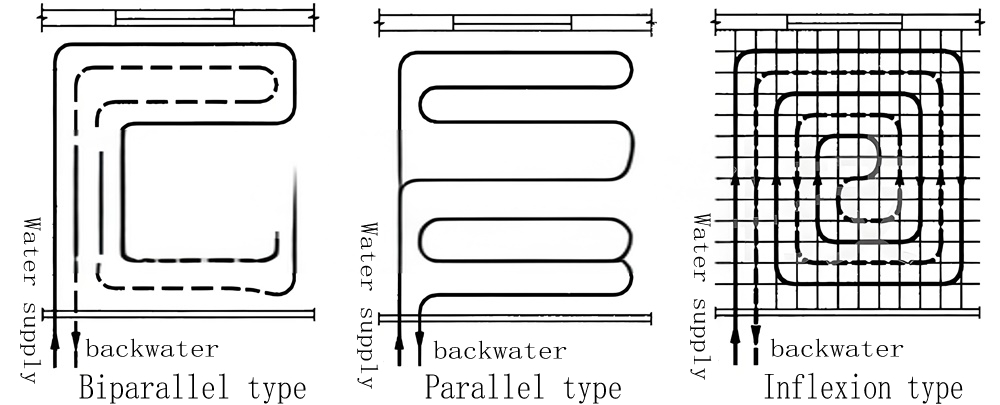

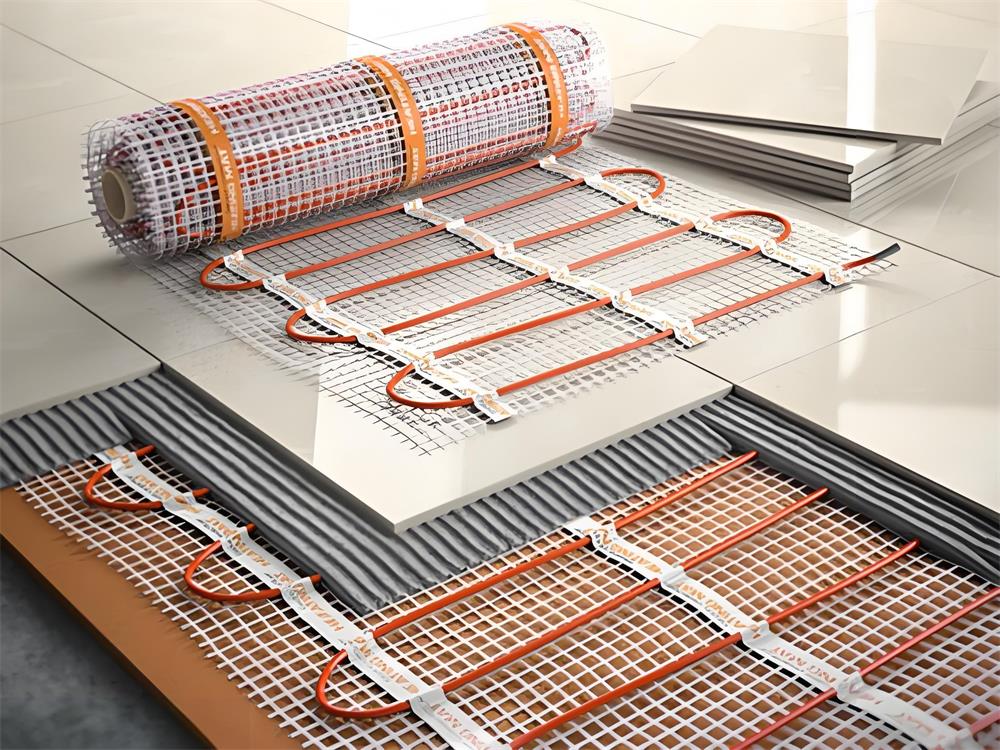

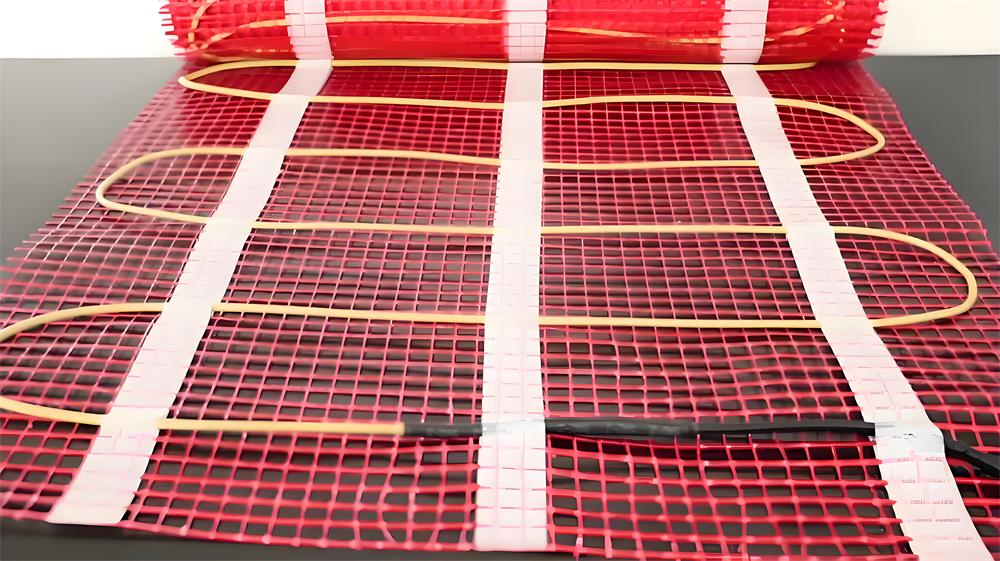

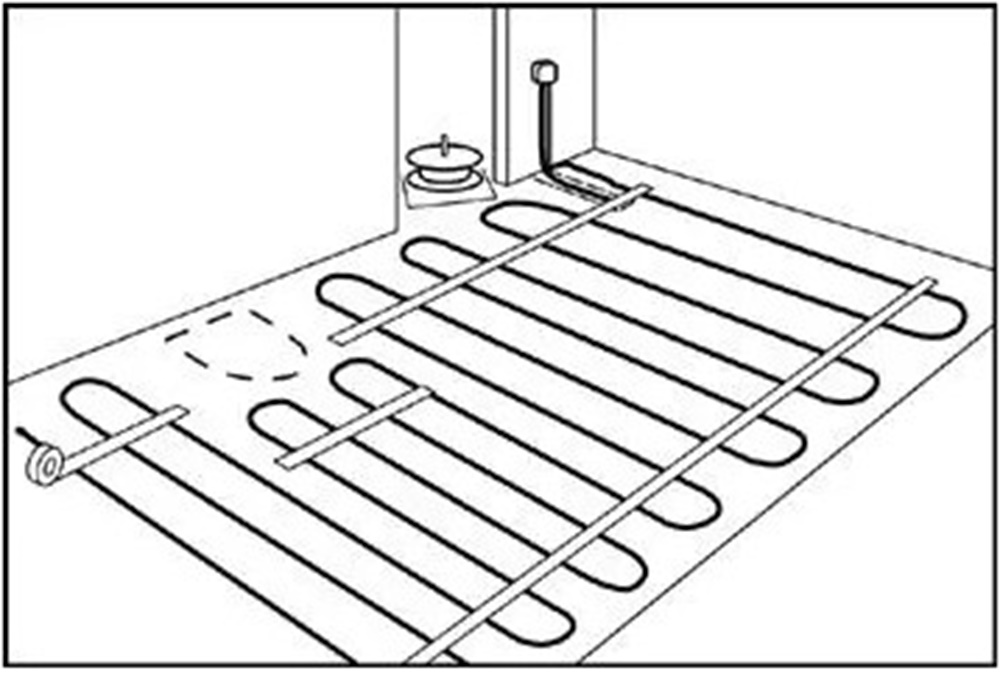

When the floor heating mat is distributed, the first step is to design a reasonable heat load distribution diagram. This requires calculating the required heat output based on the area of the room, the insulation condition and the required temperature. Next, choose the appropriate wiring mode, the common serpentine wiring and zigzag wiring. Serpentine wiring is suitable for large area, irregular shape of the room; The zigzag wiring is more suitable for the space with small area and regular shape. When wiring, it is necessary to ensure that the gap between the floor heating pads is uniform to avoid local overheating or undercooling caused by uneven heat.

In the wiring process, it is also necessary to pay special attention to avoid acute Angle bending, because this will increase the wear of the floor heating pad and affect the heat conduction efficiency. Use special tools and clamps to secure the floor heating pad to ensure its stability in concrete or screed. The length of each floor heating pad should be as consistent as possible, which helps to achieve an even distribution of heat.

The optimization of the floor heating system is not only in the wiring process, but also in cooperation with other systems such as temperature control systems. Modern temperature control technology can automatically adjust the heat output according to the temperature difference between indoor and outdoor and the comfortable temperature set by the user through intelligent adjustment, thus achieving the purpose of energy saving and improving comfort. Combined with the smart home system, users can even remotely control the temperature at home, further improving the convenience and intelligence of the floor heating system.

When carrying out the heating mat line, the following points should also be paid attention to: to ensure that the ground is dry and smooth, to avoid moisture or damage to the heating mat; Taking into account the functional differences of different rooms, reasonable distribution of heat output, such as the bedroom may need higher temperatures, while the storage room is relatively low; Check the operation status of the system regularly, find and solve problems such as water leakage and blockage in time, and ensure the long-term stable operation of the floor heating system.

Floor heating wire is a complex art that combines the principles of physics, materials science and modern technology. The correct wiring method and optimization strategy can not only improve the efficiency and comfort of the floor heating system, but also reduce energy consumption, and realize the dual advantages of economy and environmental protection. With the continuous progress of science and technology and the improvement of people's quality of life, the art and science of floor heating mat will continue to evolve, bringing warm and comfortable winter experience to more families.

The calculation method of laying accurate underfloor heating cable

2024-11-25The installation of an underfloor heating system is not random; it requires precise planning and calculation to ensure optimal heating efficiency and energy efficiency. This article will discuss the method and steps of calculating the floor heating cable of a house in detail to help readers understand and implement this process.

The core of the floor heating system lies in the laying of the floor heating cable. The laying density, layout and total length of the cable are directly related to the heating effect and energy consumption of the room. Therefore, calculating the number and layout of floor heating cables required for a room is a key step to ensure the performance of the floor heating system.

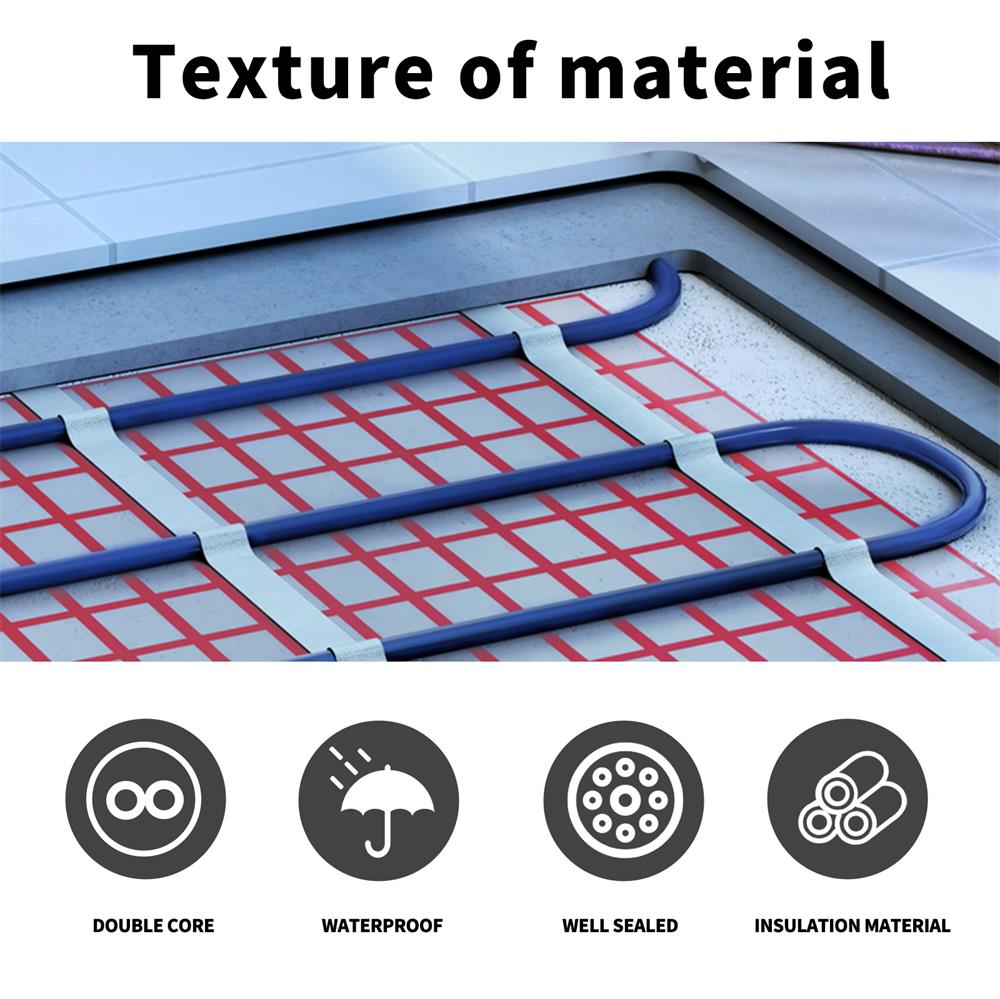

We need to understand the basic working principle and types of underfloor heating cables. Floor heating cables are usually divided into two types: single guide cables and double guide cables. Single-lead cables refer to cables with only one current loop, while double-lead cables have two current loops that can transmit heat in both directions. Two-guide cables are generally considered the better choice because of their higher thermal efficiency and more uniform heat distribution. However, the cost of the two-lead cable is also relatively higher.

After determining the type of cable, the next step is to calculate the required cable length. This needs to be calculated based on the actual area of the room, the power of the selected cable, and the target room temperature. A common calculation method is to first measure the area of the room (square meters), and then determine the power required per square meter (watts/square meters) according to the selected cable specifications. For example, if the cable power selected is 100 watts/m2 and the room area is 20 m2, the total power required for the entire room is 2000 watts. Depending on the power of the cable, the required cable length can be calculated. If the power of a cable is 200 watts/meter, then 2000 watts requires 10 meters of cable.

However, the actual laying length of the cable also needs to take into account the laying mode. Common laying modes include serpentine laying and zigzag laying. Serpentine laying can save cable length, but may lead to uneven heat distribution; Although more cables are used in zigzag laying, the heat distribution is more uniform. In actual calculation, you need to adjust the cable length according to the laying mode.

In addition to the length and laying mode of the cable, other factors need to be considered, such as the thermal conductivity of the ground material, the thermal insulation performance of the room, etc. These factors all affect the efficiency of the underfloor heating system and the number of cables required. For example, if the ground material has poor thermal conductivity, it may be necessary to increase the laying density of the cable to ensure the heating effect.

The operating cost of electric underfloor heating mats long-term benefits and energy-saving strategies

2024-11-25When seeking home heating solutions, electric floor heating mats have been widely welcomed for their advantages of easy installation, high comfort, and space saving. Meanwhile, is the underfloor heating mat expensive to operate? It has become a question for many families. So understanding its operating costs is crucial. This article will explore the operating costs of electric underfloor heating mats, including electricity consumption, efficiency improvement strategies, and the possibility of long-term savings.

The operating cost of electric floor heating mats mainly depends on their electricity consumption, which is directly related to electricity rates and the frequency of use of floor heating mats. Electric heating pads are usually measured in kilowatt hours, and their energy consumption depends on multiple factors:

1. Power of underfloor heating mat: The higher the power of underfloor heating mat, the faster its heating speed, but the corresponding power consumption is also higher.

2. Usage duration: The longer the underfloor heating mat runs every day, the more electricity it consumes.

3. Set temperature: The higher the set ground temperature, the more electricity the underfloor heating mat consumes.

4. Room insulation performance: Rooms with poor insulation performance can cause rapid heat loss, forcing underfloor heating mats to operate more frequently to maintain temperature.

To reduce the operating cost of electric floor heating mats, we can adopt the following strategies to improve efficiency.

1. Optimize temperature control settings: By using a programmable thermostat, the temperature can be automatically adjusted according to daily habits, reducing unnecessary heating.

2. Improve home insulation: Strengthen door and window sealing, increase insulation materials for walls and roofs, and reduce heat loss.

3. Partition control: Use independent temperature controllers in different areas to heat specific areas only when needed.

4. Utilize peak and valley electricity prices: Combining with local electricity pricing strategies, preheat during periods of lower electricity prices to reduce overall electricity costs.

Although the initial investment in electric floor heating mats may be higher than traditional heating systems, their operating costs may be more economical in the long run.

1. No maintenance costs: Electric floor heating mats require almost no maintenance, reducing long-term maintenance costs.

2. Long service life: The service life of electric underfloor heating systems can reach more than 25 years, far higher than traditional heating systems, reducing replacement frequency and related costs.

3. Energy efficiency improvement: With the continuous advancement of technology, new electric floor heating mats have higher energy efficiency and lower long-term operating costs. Overall, is the underfloor heating mats expensive to run? When making decisions, we should consider our own needs, budget, and long-term sustainability.

The possibility of connecting thermostat with floor heating is discussed

2024-11-25How to effectively control the temperature of this heating method, in order to achieve both energy saving and comfortable effect, is a matter of great concern to users. The use of the thermostat seems to be the key to solving this problem, but whether it can be directly connected to the floor heating system through the socket is a technical detail issue that needs to be carefully explored.

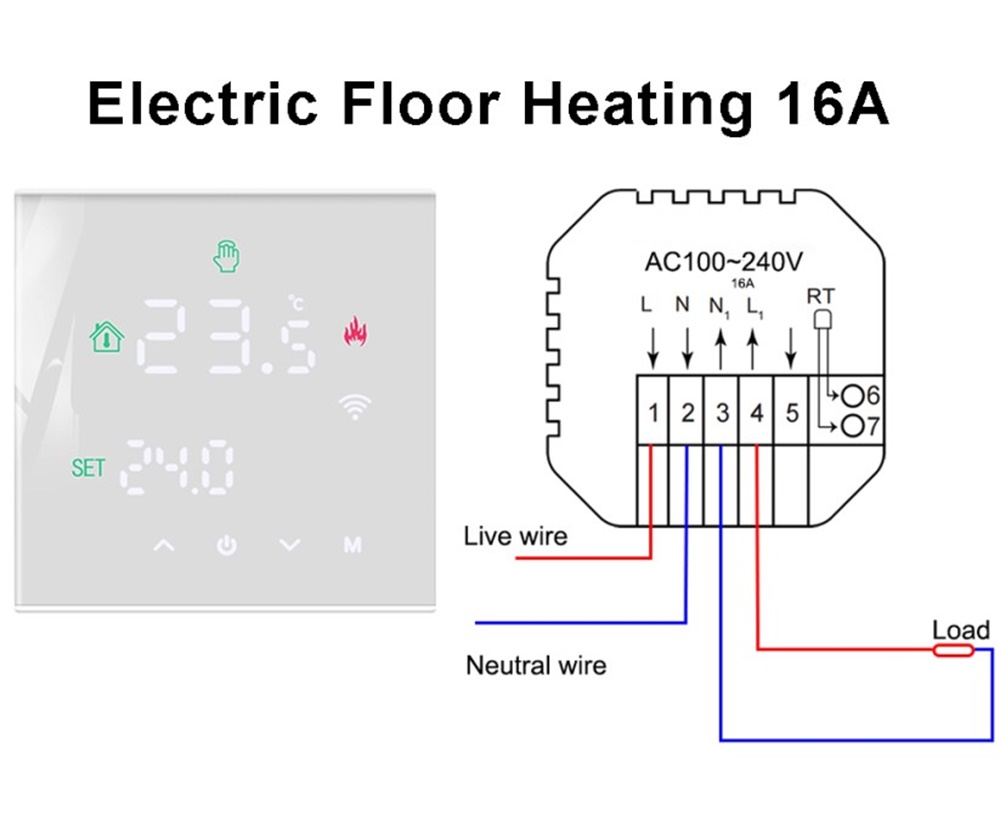

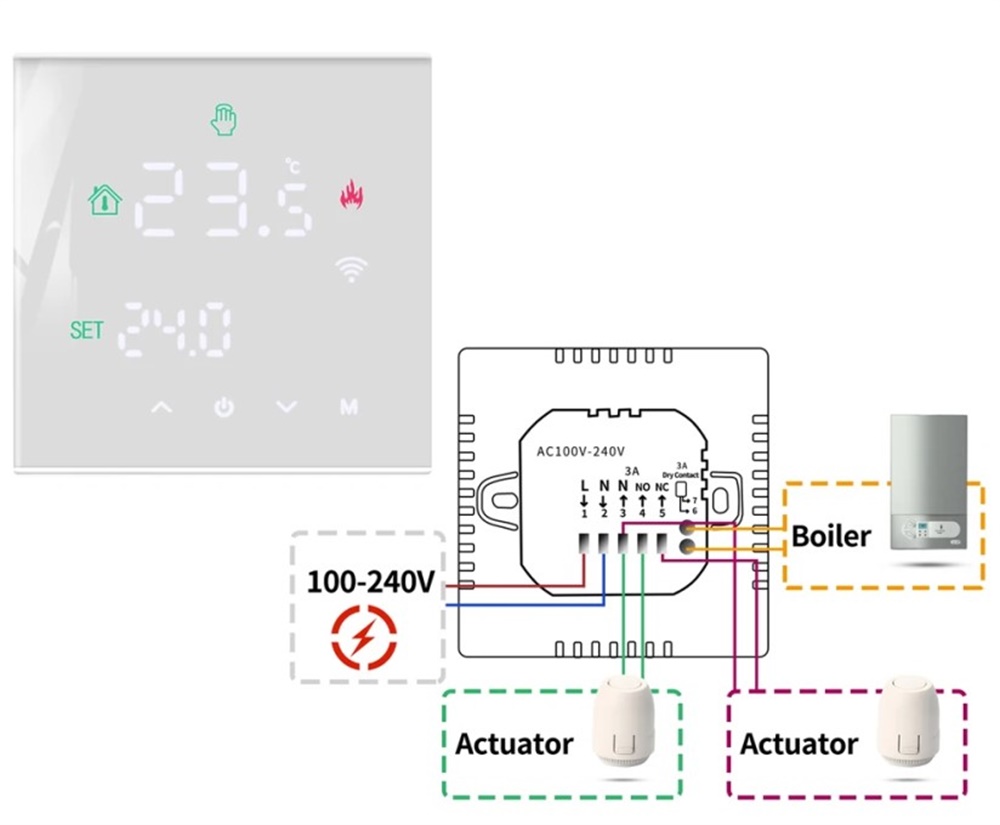

The electric heating system generates heat through the electric heating wire or the electric heat film, and its temperature control method is more direct. The temperature control equipment of electric heating floor heating can be directly cut off or connected to the power supply, so as to control the working state of the ground heating element. In this system, the thermostat can be designed as a direct plug in form, through the temperature sensor to detect the room temperature, and automatically control the heating element to start and stop, to achieve accurate temperature control. This way not only responds quickly, but also saves energy more effectively and improves the working efficiency of the floor heating system.

From a technical point of view, whether the thermostat can be directly connected to the floor heating system through a socket depends on the type of floor heating system. For the hydropower heating system, due to the limitations of its working principle, the thermostat can not be directly plugged in, but should be controlled by the mechanical valve to adjust the temperature. For the electric heating system, it is completely possible to achieve a direct electrical connection between the thermostat and the heating element to achieve more accurate and efficient temperature control.

How the thermostat is connected to the underfloor heating system depends on the type of underfloor heating system. For the water and electricity heating system, the thermostat indirectly regulates the temperature through the control valve; For the electric heating system, the direct electrical connection between the thermostat and the heating element can be realized. When choosing a floor heating system, users should consider various factors and choose the temperature control scheme that best suits their needs to achieve both energy saving and comfortable living environment.

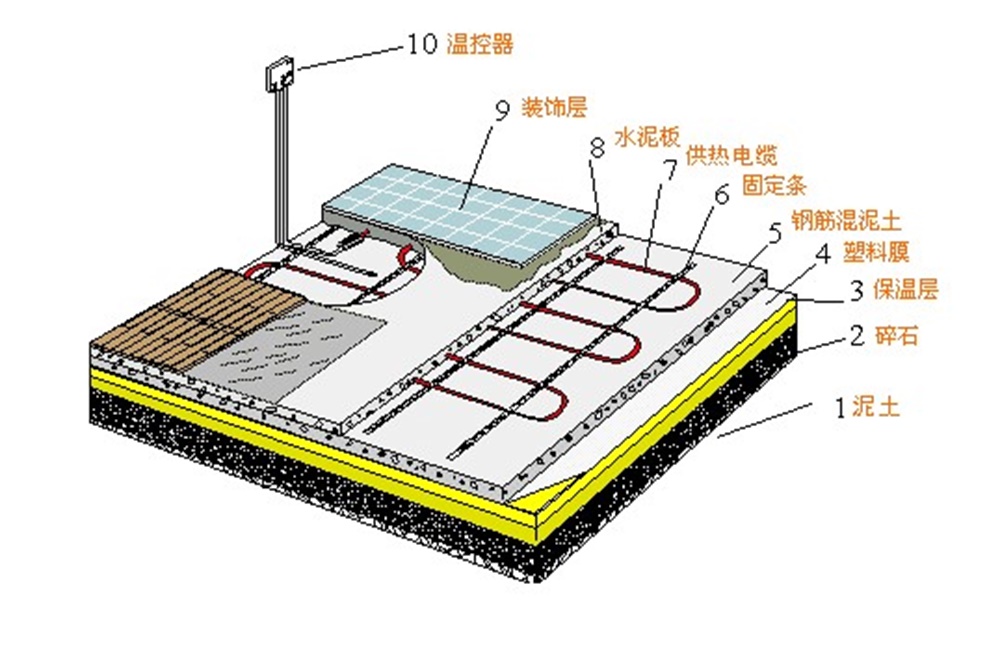

underfloor electric heating systems

2024-11-25Underfloor heating is being employed by more and more people, so how does the underfloor heating system work? How does it work? Let's find out.

Underfloor electric heating system, as the name suggests, is the electric heating element installed under the floor, through the way of electric conversion to generate heat, so as to provide uniform, comfortable, lasting heating for the room. This heating method can not only save space, but also keep the indoor environment clean and tidy, and more importantly, it provides a more healthy and environmentally friendly heating method.

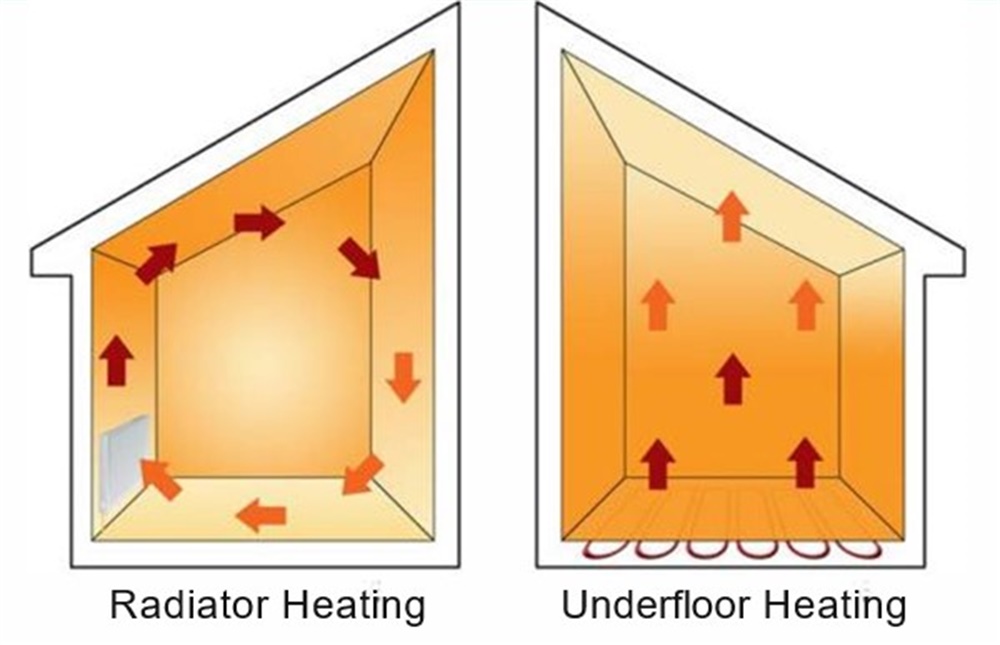

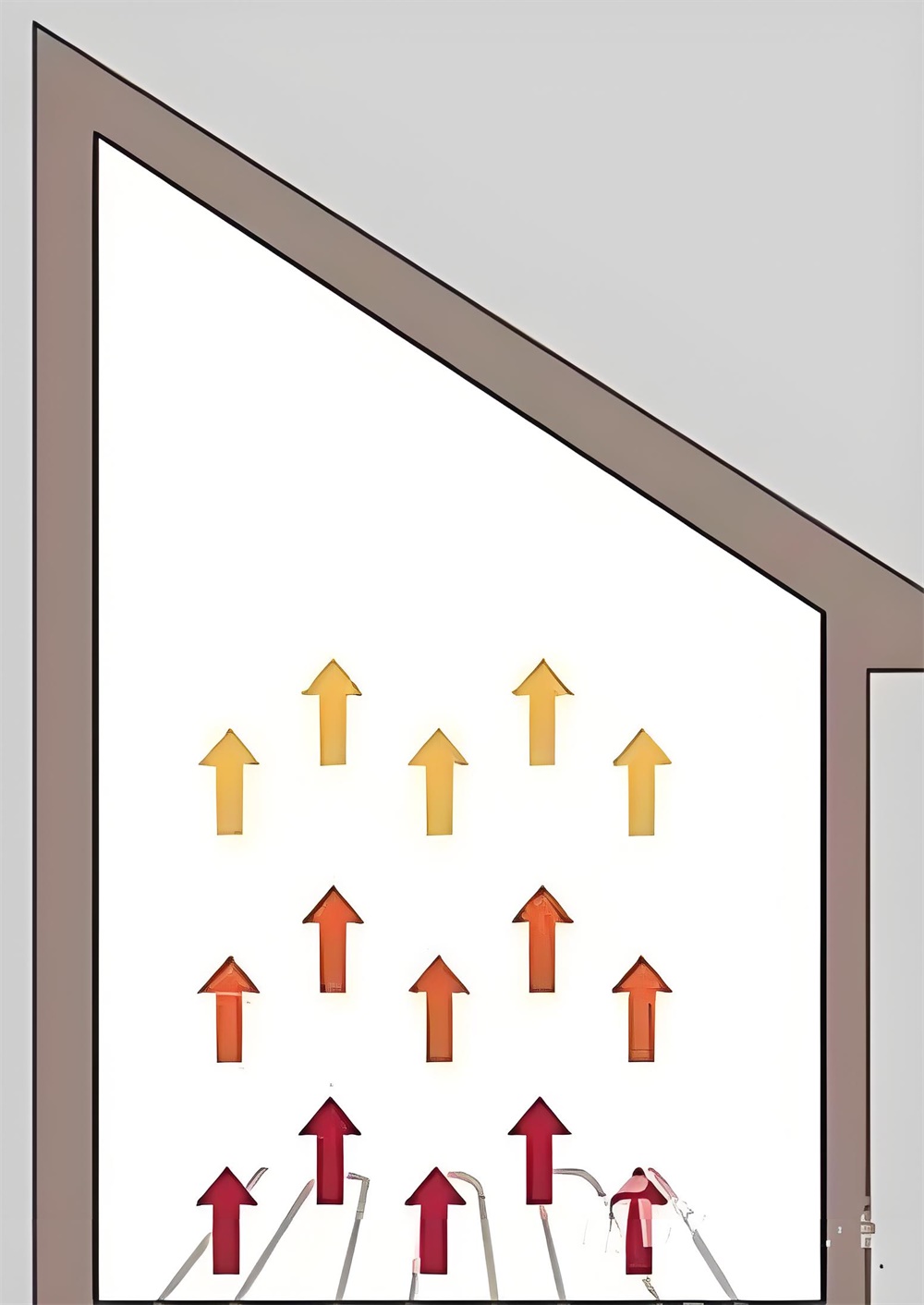

So how does an underfloor heating system convert electrical energy into the warmth we can feel? The secret lies in how it works. In short, the process can be summarized into three basic steps: electrothermal conversion, heat conduction, and heat convection.Electric heating conversion is the starting point of underfloor electric heating system. When the system is turned on, the heating elements installed under the floor begin to work, which are usually heating cables or heating films made of special materials. These electric heating elements, when energized, produce joule heat, which is the conversion of electrical energy into heat. This step is the foundation of the entire heating process, but also the most critical step.

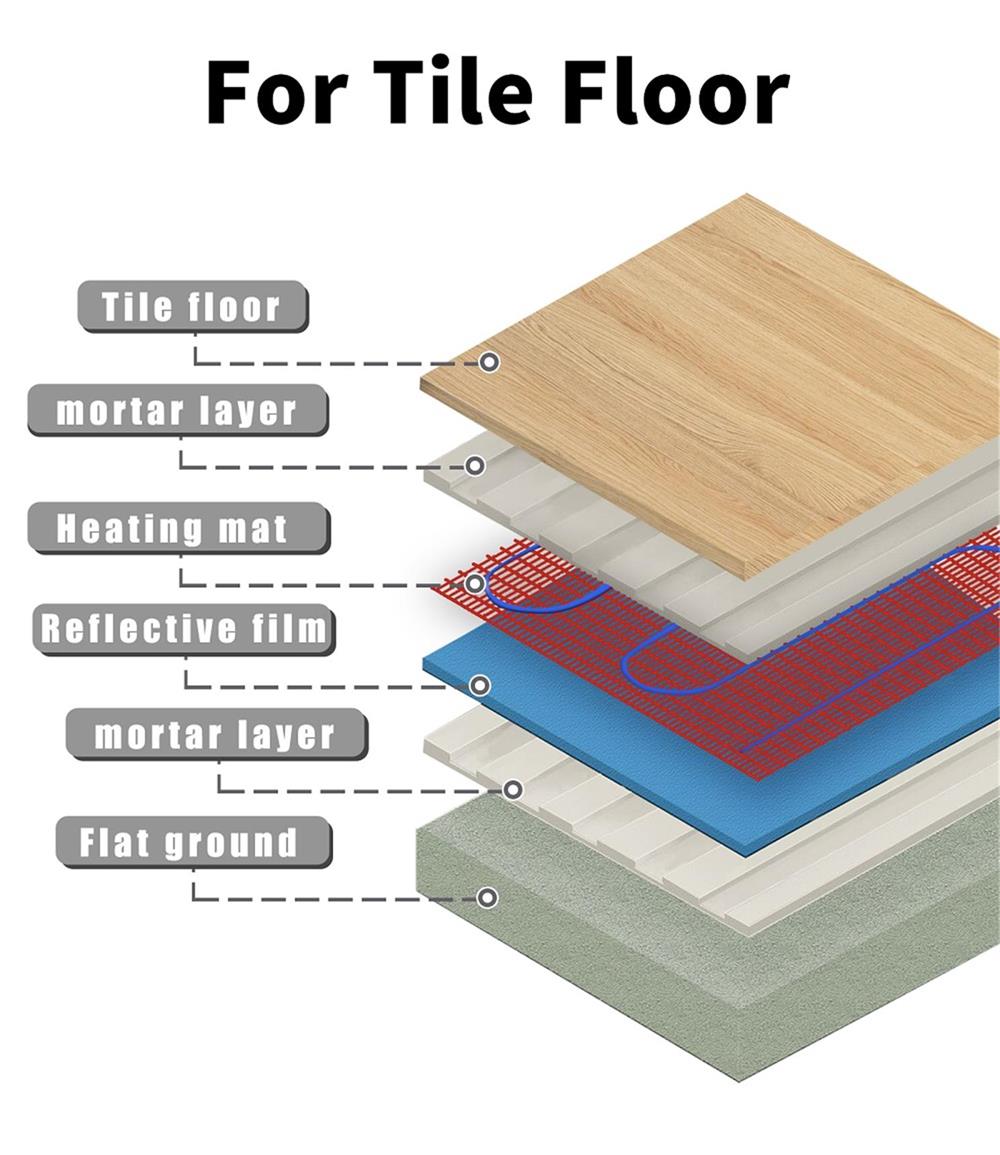

Heat conduction is the bridge of heat transfer. The heat generated is conducted through the floor material. Different floor materials, such as tile, wood flooring or composite materials, have different heat transfer efficiency. But no matter what kind of material, the heat will be evenly transferred from the electric heating element to the floor surface, which makes the floor itself become a large cooling surface.

Finally, there is heat convection, which is the way heat is transferred to the indoor environment. As the floor surface temperature rises, the nearby air is heated and rises, forming air convection. This natural phenomenon carries heat to all corners of the room, while forcing cold air down near the floor to be heated up again, creating a circulating heat convection system. In this way, the temperature of the entire interior space will gradually increase to reach the preset comfortable temperature.

With the advancement of science and technology, the underfloor heating system is also constantly optimized and upgraded. Some of our underground electric heating systems can now be controlled remotely via a smartphone app, allowing users to turn on the heating early on the way out and enjoy a warm hug when they get home. Other systems use more advanced insulation materials and more efficient electric heating elements to reduce energy consumption and improve heat conversion rates.

The working principle and working process of the underfloor electric heating system not only shows the charm of modern technology, but also provides us with a warm and comfortable living environment. In this cold winter, when we enjoy the warm floor, perhaps we will more deeply understand that warmth begins with the steps, and technology makes this warmth more possible.